salle de controle centrale cimenterie

-

de travail et le principe de concasseur giratoire

-

spécifications pdf de l usine de concassage

-

Meulage de pierre de impacto horizontal planta

-

Profil Concasseur projet Pmegp

-

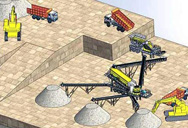

des plans dexploitation de carrière

-

machine à séparée de Fer Cuivre au Rwanda

Technologies and services for pulp production

ANDRITZ PULP PAPER supplies one of the world’s best technologies and valuable services for pulp production – chemical, mechanical, or recycled fibers. Complete production lines or individual components for your pulp

Bavarder sur Internet

All Pulp Mill Equipment At Affordable Rates

2024.1.4 Buy Pulp Mill Equipment At Affordable Rates. A pulp mill is a mechanical facility for the formation of pulp. Pulp mill used wood, wood

Bavarder sur Internet

Used Equipment For The Pulp and Paper Industry - Can-Am

Welcome to Can-Am Machinery. We have been a dealer of used equipment for the pulp and paper industry since 1988. With 250,000 square feet of warehouse space and over 8,000

Bavarder sur Internet

ANDRITZ capabilities for pulp production

Our technology portfolio for pulp production comprises equipment for every process in the modern pulp mill: wood processing, fiberline, bleaching, deinking, chemical recovery, and

Bavarder sur Internet

Deinking systems - Andritz

ANDRITZ is one of the leading suppliers of complete systems for deinked pulp – from pulping to storage, including sludge and reject treatment. Extensive system know-how,

Bavarder sur Internet

PULP PAPER (China) - andritz.cn

ANDRITZ PULP PAPER has a complete portfolio of systems for pulp and paper production: from the woodyard to the finished product. This includes. Processing of logs,

Bavarder sur Internet

Debarking systems - Andritz

ANDRITZ offers two excellent debarking technologies applicable for all types of wood and capacities, which minimize wood loss and recover bark in a log processing operation.

Bavarder sur Internet

ANDRITZ capabilities for chemical pulp production

Contact us. +86 (757) 8202 3530. pulpandpower.cn@andritz. Contact us. ANDRITZ delivers complete production lines or individual components for your pulp mill, including

Bavarder sur Internet

The Pulp and Paper Making Processes - Princeton

2007.3.19 THE PULP AND PAPER MILL Although there are several chemical and mechani-cal pulping methods used for delignifying wood (table 2-l), separating fibers, and removing discol-oration, all integrated pulp and paper mills involve the same general steps in the manufacture of pulp and paper. These steps include: 1 ) raw material

Bavarder sur Internet

First Quality Closes Purchase of Domtar's Dryden Mill

08.01.23. First Quality Enterprises announced the successful closing of its previously announced acquisition of Domtar Corporations ’ pulp mill located in Dryden, Ontario, Canada (the “Dryden Mill”). The Dryden Mill produces high quality Northern Bleached Softwood Kraft pulp for customers in North America. The Dryden Mill will operate as ...

Bavarder sur Internet

Growth on the horizon - Andritz

Fibria is the largest market pulp pro-ducer, with about 12% of the world’s pro-duction. When we talk hardwood, we are talking 22%. And, if only eucalyptus is con-sidered, our production represents 37% of global production. Our customers use our pulp for tissue (52%), printing/writing (25%), and 23% for specialties.

Bavarder sur Internet

Brownstock washing – A review of the literature - TAPPI

1 天前 in the receiving waters associated with kraft pulp mills [8,9]. Pulp washing provides desirable benefits associated with increased efficiency in both screening and bleach-ing of the pulp [3,7]. Additionally, pulp quality is also improved by good washing [1,3-6]. In short, when brown-stock washing is performed poorly, all areas of the mill are

Bavarder sur Internet

Paper Mill Equipment, Used Paper and Pulp Machines at

TRUSTED GLOBAL SUPPLIER. Peak Machinery has been supplying its customers around the world with. high-quality pulp and paper mill equipment since 2003. We carry a. broad selection of spare parts and equipment that is now approaching. 5,000 items in-house. Call us at + (612) 810-1955 for a quote.

Bavarder sur Internet

Carbon dioxide capture from the Kraft mill limekiln: process

2023.3.26 In this work, a techno-economic assessment of carbon dioxide capture from limekiln flue gas of a pulp and paper mill (Mill A) and a linerboard mill (Mill B) using a Monoethanolamine (MEA) absorption desorption process was carried out. We coupled the ASPEN Plus simulator with a derivative-free optimization (DFO) tool to identify the

Bavarder sur Internet

Paper Mill Liquidation Rabin Worldwide

2022.8.30 Whether a fully integrated paper and pulp mill, or simply a single piece of machinery or equipment, it requires specific expertise to navigate the complexities of asset liquidation for the paper industry.Rabin has experience appraising and liquidating the equipment used in converting wood chips into fiberboard, as well as machines used in re

Bavarder sur Internet

Paper Technology Journal - Voith

2023.3.21 was made to use eucalyptus pulp. The transport costs for the raw material are minimal. Due to the nearby pulp mill supplying the paper machine with steam and power, it was not necessary to invest in a power plant. In addition, the waste water of the paper mill is disposed of in the pulp mill so that a separate clarification facility was not ...

Bavarder sur Internet

Paper Machines: Pulp Mill Levstal

2024.1.14 A pulp mill is a manufacturing facility that converts wood chips or other plant fiber source into a thick fiberboard which can be shipped to a paper mill for further processing. Our tech team provides manufacturing, repair, maintaining, and upgrading of pulping mills. We offer not only design and development but also complex maintenance ...

Bavarder sur Internet

Minimization of Environmental Impact of Kraft Pulp Mill

2021.8.18 Kraft mill effluents are characterized by their content of suspended solids, organic matter and color due to the presence of lignin, lignin derivatives and tannins. Additionally, Kraft mill effluents contain adsorbable organic halogens and wood extractive compounds (resin acids, fatty acids, phytosterol) and show high conductivity due to the

Bavarder sur Internet

Environmental Consequences of Pulp and Paper Manufacture

Sludge from bleach kraft pulp mills contains a wide variety of chemicals of both natural origin and originating de novo from pulping and bleaching activities. The commonly tested regulatory chemical parameters include chlorinated dioxin congeners and heavy metals, together with agriculturally orientated parameters such as carbon nitrogen ratio ...

Bavarder sur Internet

Odor and Fallout Control in a

2023.8.23 The combination of black liquor oxidation and controlled oxygen in the flue gas has reduced sulfur emission from around 5000 lb/day to less than 500 lb. Under ideal conditions, we have been below 100 lb/day. Lime Kiln. One other source of odor release in a kraft mill is the lime kiln.

Bavarder sur Internet

Torrefaction of kraft pulp mills sludges Scientific Reports

2023.12.14 The carbon content of the PS, SS and MIX submitted to torrefaction at 320 °C for 60 min increased about 53%, 7% and 24%, respectively, compared to the references. The oxygen contents of the ...

Bavarder sur Internet

Minimum Impact Mill Technologies SpringerLink

For groundwood pulp or thermo mechanical pulp (TMP) a log cleanliness of 98–99 % is usually required, but if the mill produces bleached softwood kraft pulp, then about 85–92 % log cleanliness is acceptable (Koskinen 1999). High bark removal requires a long residence time of logs in the drum and wood loss may become high.

Bavarder sur Internet

100 years and beyond – Dryden Mill - The Forestry

2020.10.25 L’usine de pâte et papier de Dryden dans le nord-ouest de l’Ontario est demeurée prospère presque tout au long du siècle ... Domtar Pulp Mill, 1 Duke Street, Dryden, Ontario P8N 3J7. MAY/JUNE 2014, VOL. 90, N 3 – THE FORESTR Y CHRONICLE 339 ... was the only equipment to be had then for drilling holes for the dynamite”(Wice

Bavarder sur Internet

Emissions from Pulping SpringerLink

2014.1.1 The chemical portion of the pulping process—cooking liquors, process equipment—and the pulp washing steps are very similar to the kraft and sulphite processes. Presently in the mills, the chemical portion of the semi-chemical pulping process uses either a non-sulphur or neutral sulphite semi-chemical (NSSC) process (Biermann 1996).

Bavarder sur Internet

Brief Description of the Pulp and Paper Making Process

2011.10.28 The main steps in pulp and paper manufacturing are: Raw material preparation and handling, Pulp manufacturing, Pulp Washing and Screening, Chemical recovery, Bleaching, Stock Preparation, and Papermaking. Pulp mills and paper mills may exist separately or as integrated operations. An integrated mill is one that conducts pulp

Bavarder sur Internet

Outlook for Market Pulp - Hawkins Wright

2022.8.30 Table 26: Market pulp capacity by mill, US southern softwood Table 27: Market pulp capacity by mill, US fluff pulp Table 28: Market pulp capacity by mill, Scandinavian birch Table 29: Market pulp capacity by mill, Northern mixed hardwood Table 30: Market pulp capacity by mill, Southern mixed hardwood and Asian hardwood Table

Bavarder sur Internet

© IEA ETSAP - Technology Brief I07 – May 2015

2022.4.11 A paper mill using imported pulp and/or de-inked paper has a lower energy use than mechanical or chemical pulping. In regard to feedstock use, the pulp yield in chemical processes is about half compared to the production of mechanical pulp from the same amount of pulpwood. A large-scale chemical pulp mill with an annual pulp

Bavarder sur Internet

REPLACEMENT OF SOFTWOOD KRAFT PULP WITH ECF

2016.6.2 elemental-chlorine-bleached bamboo kraft obtained from a pulp mill was compared to a NBSK. Figure 1 shows that the bamboo kraft pulp required much less refining than the NBSK pulp to reach a target water retention value (WRV). Refining with a specific edge length of 1.12 km/s gave a more gentle refining and slower WRV development.

Bavarder sur Internet

EIB SECTOR PAPERS

2016.5.19 The annual investments of the European pulp, paper and board industry amount to some ECU 7 bn. The industry is very capital intensive and a typical investment cost for a paper mill is about ECU 500 million and for a modern pulp mill ECU 800 million. Due to technological development and economies of scale, the average size of new mills

Bavarder sur Internet

ANDRITZ successfully starts up main equipment for

2021.10.14 The new system features a capacity of 100 bdmt/d and processes 100% wheat straw to produce bleached straw pulp for the mill’s own tissue production. As raw material for pulp production, the facility mainly uses FSC- and/or PEFC-certified thinning and waste wood from the area surrounding the mill.

Bavarder sur Internet

Brief Description of the Pulp and Papermaking Process

2018.2.15 An integrated mill is one that conducts pulp manufacturing on-site. Some integrated pulp and paper mills perform multiple operations (example, chemical pulping , bleaching , and papermaking; pulping and unbleached papermaking, etc.). Nonintegrated mills have no capacity for pulping but must bring pulp to the mill from an outside source.

Bavarder sur Internet

(PDF) Mill evaluation of an intensified mechanical pulping process ...

2018.7.19 The state-of-the-art PM, combined with high-quality pulp, allow the mill to meet the changing needs of printers. In this article the author describes the new 220,000-ton/yr news print PM at ...

Bavarder sur Internet

What Is The Pulp Mill? Digester, Disc Filter, Twin Roll Press

2018.1.24 The pulp mill machine (also called paper pulping machine, or paper pulp making machine) refers to the required equipment for separating plant materials into fiber. There are three main paper pulping processes like chemical pulping, mechanical pulping and chemi-mechanical pulping. Relative paper pulp mills include pulp digester, twin roll

Bavarder sur Internet

Chapter 2 Brief Description of the Pulp and Papermaking

2018.2.14 Brief Description of the Pulp and Papermaking Process. Abstract The paper manufacturing process has several stages—raw material preparation and handling, pulp manufacturing, pulp washing and screening, chemical recovery, bleaching, stock preparation and papermaking. Paper produc-tion is basically a two-step process in which

Bavarder sur Internet

Kravas Equipment Inc. - Ask Questions, Offer Solutions

Kravas Equipment is one of the largest suppliers of new, surplus and rebuilt equipment in the Western United States. Kravas Equipment Inc. is a family owned business that was founded in 1985; our motto is simple, "Ask Questions, Offer Solutions." Kravas Equipment started with used equipment for the Pulp and Paper industry. We have expanded to

Bavarder sur Internet

© IEA ETSAP - Technology Brief I07 – May 2015

2022.4.11 A paper mill using imported pulp and/or de-inked paper has a lower energy use than mechanical or chemical pulping. In regard to feedstock use, the pulp yield in chemical processes is about half compared to the production of mechanical pulp from the same amount of pulpwood. A large-scale chemical pulp mill with an annual pulp

Bavarder sur Internet

Most Productive Pulp Machine Cost Parason Machinery

2024.1.2 The average cost is around $10,000. The types of equipment used for washing or dewatering of the pulp are Vacuum Drum Washer, Twin Roll Press, Single Screw Press, Disc Filter, Gravity Disc Thickener, etc. The washing equipment price ranges from 1$0,000 to $20,000. Bleaching is done to remove the inks and stains from the pulp.

Bavarder sur Internet

ANDRITZ capabilities for pulp production

Our technologies for mechanical pulp production and recycled fiber processing are among the best available. Our technology portfolio for pulp production comprises equipment for every process in the modern pulp mill: wood processing, fiberline, bleaching, deinking, chemical recovery, and pulp drying/baling. Every component is designed to work ...

Bavarder sur Internet

Articles liés

- kobelco compagnie des mines de charbon

- images de concasseur de lignes de guidage

- cast broyage billes en acier

- concasseur à percussion jce604

- fournisseurs de gravier et de sable dans tarlac

- portable usine de lavage de lor

- granit usine de concasseur de 20 à 30

- machines de traitement au jet de sable en Inde

- carrière de prix du pétrole

- processus de minerai de fer organigrammes

- liste des produits chimiques de raffinage de l or

- comment installer un broyeur wc

- de pierre à chaux broyeur de pierres à Nagpur concasseurs miniers

- crédit de broyeur de pierres

- allemagne utilise des equipements de concassage

- ligne pierre de concassage équipement de récupération de lhématite

- la pression de broyage de ciment

- broyage ciment fabricant de broyeur à boulets en Inde

- moteur pour convoyeur a lattes

- différence entre la balle de broyeur Indonésie charbon

- fabricants de barre de fer au Congo

- miniaciéries concasseur de minerai léquipement de

- cot de production de lusine de broyage feldsphar

- lamel doublure cru moulin ciment plante

- la cte et la structure d'une France de traitement du charbon

- sur le site de concassage du béton en géorgie

- mineurs de charbon outils et l'equipement

- mailles rouleau de concassage

- fabricants de filtres industriels

- moulins à café Canada minéraux de nickel