roues contrle de la poussière du concasseur

-

moulin a poudre fine

-

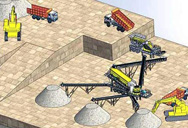

exploitation minière du charbon

-

fabricants de minerai de fer de concassage inde

-

espagne usine de platre à vendre

-

à petite échelle en pierre de concassage

-

Meulage de pierre paja vertical

Construction, Working and Maintenance of Crushers for

2018.12.26 3 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance. Crushers for Bulk Materials. Crushers and

Bavarder sur Internet

Chapter 75 Operation and Maintenance of Coal

2023.2.13 Coal screen and coal crusher are the key equipment of coal conveying system in thermal power plant (Lang 1998;Zhaoetal2001a, b). Coal conveying system

Bavarder sur Internet

Optimal operation of coal conveying systems assembled with crushers ...

2017.7.15 A coal conveying system is an energy conversion system from electrical energy to mechanical energy, where crushers are usually assembled with conveyors to

Bavarder sur Internet

煤炭破碎机_百度百科

中文名 煤炭破碎机 外文名 Coal crusher 别 名 双级破碎机 功 能 主要是针对高水份含量的煤炭难破碎的难题 用 途 一般用作粉碎煤矸石往煤里参,或者粉碎煤炭做生活之用 目录 1 产品特点 2 产品用途 3 工作原理 4 产品优点

Bavarder sur Internet

Operation and Maintenance of Coal Conveying System

2013.1.1 Policies and ethics. This paper based on our country current coal conveying system in thermal power plant, on the basis of typical screening and crushing mechanical

Bavarder sur Internet

McLanahan Coal

McLanahan offers a variety of screening solutions to separate coal into products according to their size. The screens employ tumbling or vibrating actions to size and separate the coal. The larger coal particles remain on

Bavarder sur Internet

How to maintain a coal crusher? - LinkedIn

2022.12.23 Maintaining a coal crusher involves regular inspections and servicing to ensure that the machine continues to operate effectively. Regular inspections should be

Bavarder sur Internet

Vibration Test and Shock Absorption of Coal

The coal crusher system is composed of the coal crusher, motor, and hydraulic coupler. It is located on the second story of the coal crusher chamber and is connected to the coal crusher chamber through the

Bavarder sur Internet

Optimization of particle size distribution in circulating fluidized ...

2019.6.15 The actual challenge for the crusher system to satisfy the subsequent CFB operation appears more severe because of the frequent variation in properties of coal

Bavarder sur Internet

Automated Coal Crushing and Conveyor System Using

2023.2.7 The coal from the coal yard is transferred to hopper with the help of conveyor 1 and once the hopper is filled the hopper sensor will detect and opens the hopper gate. The time for which the hopper gate will be opened depends on the size of the hopper that is the time taken to unload the coal from the hopper is given to TP block and thus the

Bavarder sur Internet

Chapter 75 Operation and Maintenance of Coal

2023.2.13 Keywords Coal handling system ring, etc. thick roller screen Hammer coal crusher, thermal power plant 75.1 Introduction Coal screen and coal crusher are the key equipment of coal conveying system in thermal power plant (Lang 1998;Zhaoetal2001a, b). Coal conveying system usually set a screening crushing machine room; broken coal and

Bavarder sur Internet

ANALISIS PENCAPAIAN TARGET PRODUKSI CRUSHER ...

2021.5.5 crusher meningkat dari 183,5 ton/jam menjadi 527,31 ton/jam, Faktor-faktor yang mempengaruhi tidak tercapainya kapasitas produksi aktual tahun 2016 yaitu supply material batubara dalam setiap ...

Bavarder sur Internet

Coal comminution and sizing - ScienceDirect

2023.1.1 Some small coal processing plants have been known to use jaw crushers, but this is probably a result of special circumstances that made it easier to obtain such crushers than a purpose-built coal crusher, and not due to any superiority of the jaw crusher in operation. 11.2.4.1. High-pressure grinding rolls and briquetting rolls

Bavarder sur Internet

Rub-Impact Fault Diagnosis of a Coal Crusher Machine by

2021.7.22 The crusher was running in a coal handling plant in steel plant. A simple schematic diagram of coal crusher with sensor orientation on bearing housing, a 3D crusher model and a photograph of Crusher NDE bearing with two sensors fixed in radial and horizontal direction are shown in Figs. 4, 5 and 6 respectively. Crusher assembly was

Bavarder sur Internet

EFFECTIVENESS SEBAGAI LANGKAH PENINGKATAN ...

2024.1.11 ANALISIS DAN PENGUKURAN NILAI OVERALL EQUIPMENT EFFECTIVENESS SEBAGAI LANGKAH PENINGKATAN EFEKTIFITAS MESIN COAL CRUSHER PT. MULTI HARAPAN UTAMA Kamari1, Sugiyono2 Program Studi

Bavarder sur Internet

Research on Structural Design of Coal Crusher House in

2020.9.10 In the coal crusher house, floor beams directly support-ing the coal crusher are not subject to vertical vibration calculation when their high-span ratio meets the require-ments of Table 1[1]. Table 1. The high span ratio limit of structural beam supporting coal crusher can be calculated without vertical vibration Dynamic disturbance force(P 0

Bavarder sur Internet

Optimal energy control of a crushing process based on vertical shaft ...

2016.1.15 In this work, the coal crusher in [8] is assumed to be a VSI crushing machine and therefore, the same system is used to simulate the optimal energy control strategy of a VSI crushing process developed in this research work. This assumption is reasonable since for pulverized hard coal-fired power plants such as those found in

Bavarder sur Internet

Vibration Test and Shock Absorption of Coal Crusher

2020.10.28 1. Introduction. Coal crushers are important auxiliary dynamic machines in thermal power plants and are used for crushing and pro-cessing raw coal. However, a coal crusher generates large vibrations when crushing coal blocks, which can affect the equipment itself, as well as the safety of the structure [1, 2].

Bavarder sur Internet

Minimization of fines generation in size reduction of coals by

2008.7.1 In Bubbling Fluidized Bed Combustors (BFBC) utilizing coal, efficient combustion requires that feed size of coal particles be in the maximum size range of 2 to 6 mm. This requires that the comminution process be effective. In this work, various types of coals have been comminuted in an impact crusher.The size reduction process is

Bavarder sur Internet

Stone Crusher Machine-CSDN博客

2023.12.30 Stone Crusher Machine. cuihuanzi2099 于 2014-11-10 12:32:34 发布. 阅读量280 收藏. 点赞数. 文章标签: shell java. Crushing machine is the exclusive compound content of particles larger than 3 mm of the total emission rate 50% or more of the crushing machine. Operations often broken by feeding and nesting into coarse grain size of ...

Bavarder sur Internet

Vibration Test and Shock Absorption of Coal

A field vibration test was conducted on the coal crusher chamber of a thermal power plant to evaluate its vibration performance. The vibration displacements and velocities of the structure, coal crusher body, and

Bavarder sur Internet

China Coal Crushing Machine, Coal Crushing Machine

China Coal Crushing Machine wholesale - Select 2024 high quality Coal Crushing Machine products in best price from certified Chinese Mining Equipment manufacturers, Mining Machine suppliers, wholesalers and factory on Made-in-China ... PE250*400 Coal Crusher Shale Crusher Brick Crusher Crushing Plant / Quarry / Crushing Plant / Stone ...

Bavarder sur Internet

Operation and Maintenance of Coal Conveying System

2013.1.1 The ring hammer coal crusher take full advantage of the kinetic energy of the hammer rings, high-speed broken. High crushing, high efficiency, low energy consumption. Power consumption per ton is only 0.4–0.6 kWh/T, about half of the impact coal crusher, hammer coal crusher third. (2) The size of broken particle is adjustable, and

Bavarder sur Internet

Optimization of particle size distribution in circulating fluidized ...

2019.6.15 The results were applied in optimizing an industrial-scale crushing system and two-toothed roll crusher of a coal gangue-fired power plant. Investigations demonstrated that the PSD can improve the combustion efficiencies of the CFB significantly by 3%, as well as a 3× extension of the original service life of the two-toothed roll crusher. ...

Bavarder sur Internet

Crushers and Mills Used in Coal Powder Plant

2012.3.14 For the Mesh hardness of coal is usually under 5, the miners can use , JC jaw crusher, , and hammer type crusher etc. to handle it. After the coal has been crushed, we need screening equipment to grade the coal

Bavarder sur Internet

MEKAR JAYA TECHNIC - Coal crusher

Coal Crusher. Coal Crusher (crusher batu bara) yang kami produksi kapasitas mulai dari 1 ton/jam - 20 ton/jam. Dengan sistem hammer mill, mudah dalam pengoperasian, dan perawatan serta kebutuhan power yang efesien. Banyak digunakan untuk menghancurkan batu bara sebagai bahan bakar boiler dan coal burner, Batu bara ukuran 50-200 mm

Bavarder sur Internet

Integrated green mining technology of “coal mining-gangue

2021.8.24 The integrated coal mining in seams 5, 8, and 9 of Tangshan Mine showed that the four backfilling surfaces of T3281, T3292, F5001, and F5002 recovered 946,000 t of raw coal and 1.18 million tons of filled gangue, with a net profit of 363.20 million yuan. The maximum land subsidence values (18, 119, 64, and 47mm) were far lower than the ...

Bavarder sur Internet

Coal Crushers utilised in Coal Processing Line - liajones - 博客园

2012.2.20 Coal jaw crusher is utilized widely as a efficient coal crusher and applied in coal processing provider. Some coal can be a mixture of coal and waste rock symbiotic parting of coal, to be able to pick the coal that requirements to become broken into smaller particle size, separation of coal and waste rock.

Bavarder sur Internet

Analysis on the impact crushing dust generation test method

2021.8.1 The impact crushing dust generation test device, developed by China Coal Technology Engineering Group Chongqing Research Institute, is mainly composed of a drop hammer, a guide rod, a crushing rod and a sample tank, as shown in Fig. 1.A certain mass of coal was placed in the sample tank and then crushed by the drop hammer freely

Bavarder sur Internet

McLanahan Coal

McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size. McLanahan crushers can take the coal producer through all stages of crushing process, from initial

Bavarder sur Internet

(PDF) Vibration Test and Shock Absorption of Coal Crusher Chambers

2020.9.15 The coal crusher generates large vibrations when crushing coal blocks, which can affect the equipment itself, as well as the safety of the structure. In order to study the dynamic characteristics ...

Bavarder sur Internet

ID: 07

SENTER 2020: Seminar Nasional Teknik Elektro 2020 ISBN: 978-602-60581-2-6 38 Gambar 4. Bentuk fisik coal crusher Batu bara yang telah dihancurkan dengan coal crusher selanjutnya di piliah atau disortir menggunakan alat yang bernama vibrating.

Bavarder sur Internet

Apa saja risiko dan kecelakaan dari Coal Crushing Plant?

2022.6.10 Umumnya, ada tiga jenis crusher digunakan dalam menghancurkan dan alat penyaring. Ini adalah crusher Primer, Crushing plant sekunder, dan crushing plant tersier. Sementara tiga jenis crusher dipilih berdasarkan sifat-sifat produk yang diinginkan, coal crushing, dan screening plant dibagi menjadi dua kelas sesuai dengan strukturnya.

Bavarder sur Internet

Analisis Efektivitas Coal Crusher Dengan Metode Overall ...

2019.10.6 Berdasarkan hasil perhitungan nilai rata-rata OEE pada mesin coal crusher pada bulan Agustus 2018 sampai Maret 2019 sebesar 55,5% dengan nilai availability rate 78%, performance rate 77%, dan quality rate 99,9% yang dimana masih jauh dengan standar dunia yaitu Avaibility >90% performance rate >95% quality rate >99,9% .

Bavarder sur Internet

Coal Preparation Systems for Boilers - Springer

2023.1.19 Since the feed-stock (coal and limestone) used for a fluidized bed (FB) boiler is coarser «6,000 I'lm) than pulverized coal «200 I'lm), a crusher-based coal preparation system is sufficient for the former. It is much simpler and less costly than that of a PC boiler. The fuel preparation plant of fluidized bed boiler comprises

Bavarder sur Internet

Design and Application of Automatic Control System for

2022.8.31 In order to improve the automatic control effect of fully mechanized mining face in coal mine, this paper combines the literature research method to analyze the disadvantages of traditional research and combines the demand analysis to analyze the structure of the automatic control system of fully mechanized mining face in coal mine.

Bavarder sur Internet

The Integration of Supervisory Control and Data

fragments to the barge. The size of the coal can be controlled by reducing or widening the distance of the coal crusher plate on the crusher machine. based on the size of the coal produced by the crushing system, this size has met the criteria for the coal industry so that this system can be used in the real world. Figure 8 shows the

Bavarder sur Internet

Dust emission from crushing of hard rock aggregates

2019.3.1 The dust generation rate of coal is mainly affected by its physical properties [15], and will present obvious differences due to its moisture, hardness, pore structure, etc. Marjo et al. [16] measured the dust concentration and particle size distribution at different distances from the dust source during rock mass crushing, and obtained the settlement

Bavarder sur Internet

Vibration Test and Shock Absorption of Coal Crusher

2023.10.15 ensure safe operation and avoid affecting work on nearby equipment[12].isguidingideologyhasbeenadoptedbythe design codes of most countries in the world.

Bavarder sur Internet

Articles liés

- Concasseur à machoires Roues

- étapes de la métallurgie de la flottaison

- socit concassage au maroc

- machines cônes de concasseurs de roches l'impact

- bresil minerai de fer hematite cout pierre de l'usine de concassage

- prix de concassage de pierre da

- pour la machine de concassage

- minerais de cuivvre au maroc

- broyeur de pierres à vendre à jhansi

- informations sur concasseur de roche

- parties principales de broyeur à boulets

- concasseur fabricants de plantes

- qui est une fonction de moulins de minerai

- pakistan aciéries taux de production levage

- le processus de casting en bronze

- ux pour extraire le minerai d'or de la maison

- La Bielle De Concasseur Indonésie Mâchoires

- plat concasseur de pierre plante

- carriere occasion Afrique concasseur de pierre en Afrique du Sud

- moulage en poudre eva

- l'equipement des dechets de construction et de demolition

- broyeur mélangeur de 5 t de capacité

- machines a broyer le bois

- investisseurs miniers à petite échelle

- concasseurs de roche laboratoire

- unite de concasseur mobile allemagne

- loi sur les mines en inde sur les broyeurs

- de broyeur a boulets bady broyeur a boulets

- mining machinery surface continuous miner

- roulis détails de guidage du moulin