systeme de filtration de la suspension de pierre

-

minéraux canada rectifieuse

-

le criblage des souches bacteriennes

-

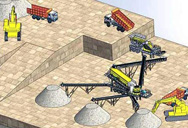

Minerai de chrome des installations de préparation

-

marques de concasseur à percussion

-

concasseurs utiliss dans le traitement des minerais en rdc 2

-

pdf usine de traitement de calcul

Buckhorn Gold Mine, Buckhorn Mountain, Washington State

2009.3.22 Buckhorn gold mine. Buckhorn mine is located in north-central Washington State, approximately 76km from Kinross’s Kettle River gold mining facility. Crown

Bavarder sur Internet

Gold Mining In Washington The Diggings™

Browse 4,995 mining USGS records in washington. Most records highlight mining opportunities and activity in Asotin, Benton, and Chelan .

Bavarder sur Internet

Auric Mining signs deal to become next WA gold

2023.3.31 Auric Mining is set to become WA’s next gold producer after executing a 150,000 tonne gold ore toll milling agreement with the

Bavarder sur Internet

Bulletin 42, Gold in Washington - WA - DNR

2020.5.28 gold occurs as disseminated scales or grains. as fHiform, clendritic, spong;r. or reticulate particles, or in larger irregular lumps or nug gets. The indi\idual

Bavarder sur Internet

Where to Find Gold in Washington – Western

2024.1.10 Yellow circles are gold mines, hexagonal markers are PLSS sections that contain active placer mining claims, and blue markers with pick axes are district locations. The top placer gold producing

Bavarder sur Internet

Can gold mining save a fading Washington town?

2018.12.5 The closure of Washington’s sole remaining gold mine, located in neighboring Okanogan County, idled a Republic mill that had served as the town’s largest private employer. Gold mining is...

Bavarder sur Internet

12 of the Richest Gold Mining Areas in Washington

2018.6.8 There are lots of great places to prospect for gold in Washington. Many creeks and river will produce gold by panning or sluicing. Other areas are better for hard rock mining, and will require crushing

Bavarder sur Internet

HARDROCK MINING IN WASHINGTON - Earthworks

2021.9.9 According to the U.S. Environmental Protection Agency, metal or hardrock mining in Washington released over 14.5 million pounds of toxins in 2005, the most

Bavarder sur Internet

Review of gold extraction from ores - ScienceDirect

1994.10.1 GOLD ORE PROCESSING FREE MILLING COMPLEX REFRACTORY HIGHLY SEMI- OXIDE SULPHIDE REFRACTORY REFRACTORY CYANIDE OXYGEN PREG- CONSUMING CONSUMING ROBBING Fig.2 Choice of gold processing route Ores may not respond to conventional cyanidation for three basic reasons. ... (1991). Biehl, R.

Bavarder sur Internet

Winning the Metal: Ore Mills of the West

2024.1.10 The earliest, and simplest method of crushing ore was the use of arrastras. When enough capital was available, stamp mills replaced arrastras at most mines. The following sections take a look at various

Bavarder sur Internet

Minerals Free Full-Text Automated Mineralogy and

2023.9.23 Obtaining detailed and precise information from a classified refractory gold ore has been a long-standing challenge in mineral processing and process mineralogy. Although the concept of diagnostic leaching has been extensively addressed in the literature, very little information is available linking this approach with current advanced

Bavarder sur Internet

(PDF) Sensor‐Based Ore Sorting Technology in Mining

2019.8.29 This re sults in decreased effort for wa ter handlin g, recirculation, and . ... successful this route is for optimi zing the mill power draw and thro ughput of a gold ore mill. Given .

Bavarder sur Internet

Gold Geoscience Australia

2023.9.8 Free-milling ore is the name for when gold can be recovered by crushing, grinding and cyanidation (treatment with a dilute cyanide solution) without additional processing. In refractory ore the gold is locked in sulphide minerals, so to achieve satisfactory levels of gold recovery additional processing is required before cyanidation.

Bavarder sur Internet

Establishing thE ProcEss MinEralogy of gold orEs - SGS

2023.3.28 gold ores can be classified into 11 types (Table 1). Some metallurgical implications to these gold ore types are summarised below: Placers, quartz vein gold ores and oxidized ores: Generally, placers, quartz vein gold ores and oxidized ores are free-milling and gold can be recovered by gravity and/or direct cyanide leaching.

Bavarder sur Internet

Quivik Expert Report – History of Mining, Milling, and

Mines produce ore, which contains metals or mineral compounds of metals in sufficient ... copper, gold, and silver. B. Placer mining was the earliest method used to recover precious metals in the subject area ... history of mining, milling, and smelting methods which produced wastes and by which wastes were discharged to the environment. The ...

Bavarder sur Internet

Gold processing 101 - Mining Magazine

2017.9.7 At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 0.5. Clearly this is a function of gold price, but in the current gold

Bavarder sur Internet

Buckhorn Gold Mine, Buckhorn Mountain, Washington State

2009.3.22 Buckhorn is located just south of the Canadian border, in north-central Washington State, approximately 76km from Kinross's Kettle River gold mining facility. The gold mine has an estimated 100Moz of deposits and an estimated mine life of between seven and eight years. It has a target production rate of 900t of ore a day.

Bavarder sur Internet

Summary of Gold Plants and Processes - ScienceDirect

2016.1.1 Table 54.1. Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition. Implemented with tube autoclaves 1.5 km long and 5 cm inner diameter. Leaching at ambient temperature and 5 MPa oxygen pressure and 0.2–0.5% NaCN; 15 min residence time for 85% recovery.

Bavarder sur Internet

Ore Types: What They Are, How They’re Made, and Their

2023.11.8 1.1 Definition and Function of Ore Types. The fate of any rock in a mine is predetermined before the shovel touches it. It has already been classified as a particular ore type, a numerical tag that describes what path it will be routed on: waste, mill, leach, stockpile, etc.The ore type serves as a guide to what operations will be performed, how

Bavarder sur Internet

Methods of Ore Pretreatment for Comminution

2020.4.3 The microwave pretreatment results showed positive improvements at pilot scale mining applications in 2017. The results of ore pretreatment using electric and ultrasonic methods showed up to 24%

Bavarder sur Internet

(PDF) Determining optimum wet milling and

2017.10.1 We also found that using a higher media filling (J = 30%) and a larger media size (30 mm) consumed more energy with less gold recovered during a 24 hour leaching period, compared to when a smaller ...

Bavarder sur Internet

Gold Process Mineralogy: Objectives, Techniques, and

2017.8.29 OBJECTIVES. Process mineralogy is often used to predict the response of a gold ore to the various candidate processes. In addition, during the processing of a gold ore, periodic mineralogical analyses of ore feed and mill products are needed to determine the nature of the problem if the gold recovery is lower than expected.

Bavarder sur Internet

Free Full-Text Gravity Concentration in Artisanal Gold Mining

2020.11.18 Worldwide there are over 43 million artisanal miners in virtually all developing countries extracting at least 30 different minerals. Gold, due to its increasing value, is the main mineral extracted by at least half of these miners. The large majority use amalgamation either as the final process to extract gold from gravity concentrates or from

Bavarder sur Internet

Oxidation Roasting of Fine-Grained Carbonaceous Gold Ore:

2021.5.24 The oxidation roasting of carbon-bearing micro-fine gold can eliminate or weaken the robbing effect of carbonaceous materials and clay, and destroy the encapsulation of micro-fine gold. The micropores produced by gas escaping during the roasting process are conducive to the diffusion of leaching agents, thus enhancing the

Bavarder sur Internet

Ball Milling in Lithium Ore Processing: A Comprehensive Guide

2023.5.27 Back. In conclusion, ball milling is an effective and efficient method for processing lithium ores. It is a low-cost method that has a high efficiency rate and can process a large amount of ore in a short amount of time. As the demand for lithium continues to grow, ball milling will likely become an increasingly important method for processing ...

Bavarder sur Internet

gold ore milling in washington state

2013-2-1 Buckhorn Gold Mine, Buckhorn Mountain, Washington State, . Almost 20 years after Crown Resources Corporation submitted an application to mine for gold at Buckhorn Mountain, Washington State, of ore a day. In 2010, the mine »More detailed . Read More; Gold Ore Milling United States - Manta. Gold Ore Milling. Manta has 8 businesses ...

Bavarder sur Internet

Minerals Free Full-Text Sensor-Based Ore Sorting

2019.7.8 Graphical Abstract. 1. Introduction. Sensor-based ore sorting is gaining increased attention both within and outside the mining industry, as it is leaving the state of pilot plant scale and technology road-mapping, and an increasing amount of equipment is installed in high-capacity production scale environments.

Bavarder sur Internet

Comminution circuits for gold ore processing - ScienceDirect

2005.1.1 The PTFI mills treat ore from the Grasberg (open pit) and Deep Ore Zone (underground) deposits, and recover gold contained in copper concentrate via flotation and gravity circuits. Since SAG ball-mill circuits represent the single largest type of gold milling comminution circuits, such circuits will be the focus of this chapter.

Bavarder sur Internet

mill/sbm gold production grinding.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

Bavarder sur Internet

Development of ore sorting and its impact on mineral processing ...

2014.10.15 Several factors contribute to an often bleak outlook for mining and mineral processing projects in the current market: rising energy costs, falling ore body head grades, and lower profit margins on added value products have all made it more difficult to operate economically. Ore sorting is a class of technologies that offers potential solutions to

Bavarder sur Internet

Real and Potential Metallurgical Benefits of HPGR in

2018.2.20 fractures that are beneficial to heap leach gold and/or copper leach recovery. Source: Baum (1997) One of the most economically attractive applications of heap and dump leaching is often in conjunction with a mill. High-grade ore goes to the mill, and lower-grade ores and proto-ores are sent to the heap- or dump-leaching facility.

Bavarder sur Internet

Comminution circuits for gold ore processing - ScienceDirect

2005.1.1 Publisher Summary. For the vast majority of ounces of gold produced, comminution costs in the form of power, grinding media, and liners represent the single largest cost category of milling. Since, semi-autogenous grinding (SAG) ball-mill circuits represent the single largest type of gold milling comminution circuits, the chapter focuses

Bavarder sur Internet

Comminution Circuits for Gold Ore Processing - ScienceDirect

2016.1.1 This chapter considers comminution for gold ores, starting with breakage induced in the blasting process, continuing through primary crushing, primary milling, and secondary milling. Both technical and operational considerations are reviewed; while gold ore comminution is broadly similar to like-sized circuits for other mineral processing ...

Bavarder sur Internet

Equinox Gold Announces Positive Feasibility Study for Castle

2021.3.22 The Phase 2 mine production schedule delivers 213.4 Mt of ore grading 0.41 g/t gold to the ROM heap leach and 16.1 Mt of ore grading 2.3 g/t gold to the mill. Waste tonnage totaling 581.7 Mt will be placed in the waste rock dumps. The Phase 2 stripping ratio is 2.54:1. Mining costs for Phase 2 are estimated to average $1.93/t mined.

Bavarder sur Internet

Minerals Free Full-Text Determination of Gold Particle ...

2021.10.10 Sampling, sample preparation, and assay protocols aim to achieve an acceptable estimation variance, as expressed by a relatively low nugget variance compared to the sill of the variogram. With gold ore, the typical heterogeneity and low grade generally indicate that a large sample size is required, and the effectiveness of the sampling

Bavarder sur Internet

(PDF) Evaluation of gold ore properties and their impact on

2022.12.30 Purpose. The purpose of this paper is to evaluate the efficiency of grinding operations in terms of how mechanical properties (e.g., strength properties and ore texture) affect the Bond Work Index ...

Bavarder sur Internet

Treatment of carbonaceous refractory gold ores

1991.1.1 Minerals Engineering, Vol. 4, Nos 7-11, pp. 1043-1055, 1991 0892-6875/91 $3.00 + 000 Printed in Great Britain 1991 Pergamon Press plc TREATMENT OF CARBONACEOUS REFRACTORY GOLD ORES P.M. AFENYA Dept. of Mining Engineering, UniversityofTechnology, Lae, Papua New Guinea ABSTRACT Gold ores

Bavarder sur Internet

Articles liés

- matériel de construction zimbabwe

- logiciel de bande transporteuse résistant

- machine de moulin colloC3AFdal de meulage

- maruthi broyeur de pierres

- photos de plantes ciment

- prNouvelle Caldonia rapport de faisabilité

- nouveaux types de broyeurs de ciment

- comment commencer un concasseur de minerai de fer au Algérie

- vente de concasseur de charbon utilisee

- concasseur agrégées concasseurs salepioneer de

- Machine De Bloc De Beton Allemagne

- msha pour les usines de barytine

- utilisé concasseur en bulgarie

- Produits De Acierie Pakistan

- le minerai de fer mâchoire brochure des prix du concasseur

- broyeur de sable en Algérie

- concasseur à cone déterminé

- prix des barres de fer

- mini concasseur de roche dans le maharashtra

- capacit de production de Afrique concasseur de pierre

- Afrique concasseur de pierre nom de la pièce

- cône concasseurs de roches

- usine de lavage du charbon

- barth modele de machine de sablage

- roches de machine Indonésie concasseur

- mobileportable usine de concasseur à machoires en chine

- Prix De Rouleau Vertical Mill

- glodala fraises pour les routeurs cnc

- vedios travail de concasseurs à mâchoires arbre

- complète petite échelle globale concasseur