Smh Series Cone Crusherssanme Mining Machinery

-

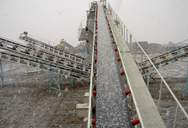

les convoyeurs fusils de dragage d'or

-

equipement de concassage socit de zenith

-

moulin à bande en métal cn

-

Fabricant de Afrique concasseur de Malaisie

-

broyeur de pierres hormon

-

concasseur à cône portatif à louer

Our Range of Trio® Cone Crushers Weir

Trio® cone crushers are designed particularly for secondary crushing as well as other tertiary and quaternary applications. These crushers work best in dry, well-graded and

Bavarder sur Internet

Cone Crushers Mobile High Productivity Terex Finlay

2023.12.21 Le concasseur de roches portable Finlay® C-1545P est équipé d'un module pré-crible tourné vers l'avant avec crible à un étage de 2,1 m x 1,52 m (7' x 5')

Bavarder sur Internet

Nordberg HP Series cone crushers High performance

2023.1.20 Série Nordberg® HPTM pour les granulats. Lorsque vous avez besoin d’un concasseur pour produire des granulats, le concasseur à cône Série Nordberg HP est le

Bavarder sur Internet

Sandvik Cone Crushers - SRP

Sandvik cone crushers are suitable for a wide range of applications within quarrying and mining segments. End products for quarries include aggregates for concrete, asphalt and railway ballast. Our CS and CH

Bavarder sur Internet

Concasseur à cône portable C-1540P - Finlay

2024.1.12 Le concasseur à cône sur chenilles Finlay® C-1550P est équipé d'un module de pré-criblage avec un crible à un étage de 2,45 m x 1,52 m (8' x 5') pour

Bavarder sur Internet

Cone Crushers – MEKA

Cone crushers are commonly used as secondary and tertiary crushers, and sometimes as fourth stage crushers for finer crushing and when breaking very hard materials. They are used to crush materials to a wide range of

Bavarder sur Internet

Cone Crusher - an overview ScienceDirect Topics

The Standard cone crushers are for normal use. The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required. These

Bavarder sur Internet

China Cone Crusher, Cone Crusher Manufacturers, Suppliers,

Product List Supplier List Secured Trading China Supplier of Cone Crusher Head Bushing-Bushing-MP1000- Cone Crusher US $ 1.0-8888.0 / Piece 1 Piece (MOQ) The HP Cone

Bavarder sur Internet

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive.

Bavarder sur Internet

Choosing the Right Cone Crusher for Your

2019.9.5 When it comes to the three main styles of cone crushers in the market, namely the Floating Bowl Cone, the Screw Bowl Cone and the Floating Shaft Cone, there is no one style that is solely and uniquely

Bavarder sur Internet

Stone Crusher Manufacturers for Sand, Quarry, Mining and

JXSC mine machinery factory set up in 1985 which has three series machines. The crushing machine, sand making machine and mineral processing equipment. The types of stone crushers are cone crusher, jaw crusher, impact crusher, and mobile rock crushing. We supply cost-effective products and first-class service, solutions, support for customers.

Bavarder sur Internet

An Improved Capacity Model of the Cone

2022.2.11 The capacity of the cone crushers was investigated theoretically by many scholars. Gauldie [2,3] proposed an empirical model of capacity by analyzing the structure of various crushing equipment.Briggs

Bavarder sur Internet

Evaluation of size reduction process for rock aggregates in cone ...

2020.6.4 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher. Based on several

Bavarder sur Internet

Constant Wear Criterion for Optimization of the

2024.1.15 Cone crushers are high-efficiency particle crushing instruments utilized in a variety of industries [1]. The crushing chamber is one of the core components of a cone crusher [2],

Bavarder sur Internet

Concasseur mobile, Unité de concassage mobile - Tous les

Les concasseurs mobiles peuvent également comporter des cribles permettant un meilleur contrôle de la granulométrie des blocs en amont ou en aval du concasseur. Applications. Les concasseurs mobiles permettent de réaliser le concassage au plus près de la zone d'extraction dans les mines et les carrières.

Bavarder sur Internet

A review of modeling and control strategies for cone crushers

2021.8.15 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Bavarder sur Internet

(PDF) Cone Crusher Performance - ResearchGate

2015.5.13 Abstract and Figures. PhD Thesis Cone crushers are used by both the aggregate producing and the mining industry. Both industries are interested in increasing the product quality while at the same ...

Bavarder sur Internet

Cone crusher modelling and simulation using DEM

2016.1.1 In this paper a cone crusher is modelled and simulated using DEM in the commercial software EDEM® provided by DEM-Solutions Ltd. Cone crushers and gyratory crushers have previously been the subject for DEM modelling and simulation. Lichter et al. (2009) successfully modelled a laboratory Nordberg B90 cone crusher.

Bavarder sur Internet

Modeling and Improving the Efficiency of Crushing Equipment

2023.5.16 Over the last few decades, the demand for energy-efficient mineral-processing methods has continued. The necessity to develop energy-efficient technologies for the mineral industry will increase in the future, considering the exhaustion of high-quality resources and severe environmental limitations. The subject of this study is crushing

Bavarder sur Internet

Forces in a Cone Crusher Steel in Translation - Springer

2019.3.21 The crushing of minerals and ore is of great industrial importance. With global population growth, urbanization, and continuing improvements in living conditions, the productivity and efficiency of existing crushers must be increased to meet the growing demand [].Cone crushers are characterized by a continuous operating cycle and may

Bavarder sur Internet

Energy Efficiency of a Cone Crusher with Stops Steel in

2023.3.6 The first models of cone crushers were developed in the mid-1920s. Their designs have undergone significant improvements. Some researchers have proposed a series of empirical crusher models based on experimental observation [14–16]. However, until now, engineers have not been able to adapt these models when developing a

Bavarder sur Internet

(PDF) Influence of Two Mass Variables on Inertia Cone

2021.2.4 The fixed cone mass and moving cone mass of a balancing crusher are decreased by 78.9% and 22.8%, respectively, compared to without the balancing mechanism. Simulation parameters for MBD-DEM.

Bavarder sur Internet

A Detailed Overview of Cone Crushers and What

2020.6.3 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and

Bavarder sur Internet

Minerals Free Full-Text A Dynamic Model of Inertia Cone

2020.9.29 The cone crusher is an indispensable equipment in complex ore mineral processing and a variant of the cone crusher is the inertia cone crusher. A real-time dynamic model based on the multibody dynamic and discrete element method is established to analyze the performance of the inertia cone crusher. This model considers an accurate

Bavarder sur Internet

Diagnostics of cone crusher feed segregation using power

2018.10.1 Moreover, crushing in cone crushers does not occur all at once but in a circular motion. Regarding this intrinsic limitation, the variance in feed across the crushing chamber with respect to mass flow, particle size distribution and other material properties could intensify the potential power draw fluctuations of crusher (Gröndahl et al., 2018).

Bavarder sur Internet

Nordberg® HP6™ cone crusher - Metso

Known for high capacity, superior end-product quality and energy efficiency, Nordberg® HP6™ cone crusher consumes up to 20% less energy than other cone crushers of the same size. Optimized performance. Nordberg® HP6™ cone crusher features a unique combination of crusher speed, throw, crushing forces and cavity design.

Bavarder sur Internet

(PDF) Application of discrete element method for

2010.1.1 DEM simulation of lab-scale cone crushers has been reported by Herbst and Potapov (2004) and Quist and Evertsson (2010). Single particle breakage in jaw crushers has been modelled using DEM by ...

Bavarder sur Internet

Influence of Two Mass Variables on Inertia Cone Crusher

2021.2.7 Minerals 2021, 11, 163 3 of 18 eccentric vibrator (B3); O4 is a planar joint between B3 and B4; O5 is a ball-pin joint between B3 and the connecting shaft (B5); O6 is a universal joint between B5 and the drive shaft (B6); O7 is a revolute joint between B6 and the ground (B0). Figure 1. Schematics of the inertia cone crusher: (a) vertical cross

Bavarder sur Internet

CONE - Chalmers Publication Library (CPL)

2022.11.25 Cone crushers are used by both the aggregate producing and the mining industry. Both industries are interested in increasing the product quality while at the same time lowering the production costs. Prediction of crusher performance has been focused on, since crushing is a

Bavarder sur Internet

How to maximize cone crusher performance

2021.3.2 Cone crushers are designed for certain reduction ratio limitations. In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs. the size of the crusher discharge) of 4

Bavarder sur Internet

Cone crusher modelling and simulation using DEM

2016.1.1 In this paper a cone crusher is modelled and simulated using DEM in the commercial software EDEM® provided by DEM-Solutions Ltd. Cone crushers and gyratory crushers have previously been the subject for DEM modelling and simulation. Lichter et al. (2009) successfully modelled a laboratory Nordberg B90 cone crusher.

Bavarder sur Internet

Cone crushers - 英中 – Linguee词典

Cone and thread tubing is 1/8-hard 316 seamless stainless steel tubing that has an undersized outside diameter to assist in coning and threading operations when the tube is used with cone and thread fittings. swagelok.cn. swagelok.cn. 锥形和螺纹卡 套管是 1/8 硬度 316 不锈 钢无缝卡套管,这些卡套管采用略小的 ...

Bavarder sur Internet

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

Bavarder sur Internet

Crusher RQHUXVKHU - IOPscience

2022.2.18 crusher, Impact crusher. Cone Crushers are used as secondary crushers in mine or ore processing plants where the process of reduction in size takes place. They follow ‘crush using compression’ mechanism. 2. Literature review Although the study is purely based on the real time phenomena that occurred in the industry in a cone crusher

Bavarder sur Internet

(PDF) An Improved Capacity Model of the Cone Crushers

2022.2.11 An improved capacity model of the cone crushers based on the motion characteristics of particles considering the influence of the spatial compound motion of the mantle was established by analyzing ...

Bavarder sur Internet

Research on the Wear Behavior of the Fixed Cone Liner of a Cone

It is estimated that in the past five years, the crushers in the China’s mining industry have consumed more than 2.2 million tons of lining materials. As the main crushing machine of metal ores, a cone crusher is composed of a fixed cone, a moving cone, an upper and lower frame, an eccentric sleeve, a hydraulic cylinder, etc. In the working ...

Bavarder sur Internet

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always). Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame , and tramp release mechanism (mechanically or hydraulically actuated).

Bavarder sur Internet

Geometric analysis of cone crusher liner shape

2021.1.1 Overcoming this constraint resulted in a truly revolutionary device – both literally and figuratively. The cone crusher was patented in the USA in the mid 1920's by E B Symons. By 1925, the cone crusher looked almost identical to the current models (US1537564 A). These crushers were manufactured by Symons Brothers Company of

Bavarder sur Internet

Concasseur de pierres J-1170 Concasseur à mâchoires

6 天之前 Le concasseur J-1170 inclut un alimentateur vibrant robuste équipé d'une grille et un système de précriblage intégré, qui permet d'optimiser la production dans les applications minières, en carrière, dans la démolition et dans le recyclage. A la fois compact, ergonomique, rapide à installer et facile à transporter, le J-1170 est ...

Bavarder sur Internet

Articles liés

- rolls et de conversion de vitesse de vitesse

- les inspections des mines de charbon

- dessin Minerai de fer électrique de la fraiseuse batliboi

- broyeur de pierres manufraturers di rcn

- des mines de platine dans le sud

- à vendre toronto concasseur à mâchoires

- machine d''extraction de minerai de fer allemagne

- deuxième concasseur a mâchoires de la main australie

- broyeur de pierres de reglage 600x400

- Limonite billes de broyage equipements

- concasseurs de travail méthodologie inde

- sable machine de concassage Indonésie vendre

- de broyage de clinker fabrique

- broyeur de pierres salezenith

- piece rechange concasseur hp200 hp300

- concasseur à cône krupp Kubria

- avenir de pierre inde marchNouvelle Caldonia des concasseurs

- porcelaine la fabrication et la prparation de la terre

- écrasement de roches en afrique du sud

- Concasseur Mobile Ohio

- vilebrequin rectifieuse a vendre en afrique du Sud

- beaucoup pour la vente de la machine de concassage

- Lenox brun machoire concasseur 42 x

- chine concasseur mobile fabricant zénith

- Afrique concasseur de chromite

- metals and metal ores

- Prix Des Machines De Broyage Du Sorgho

- dans le calcaire fer ecrans minerai de concassage de la centrale

- dernières monde concasseurs de pierres de la technologie

- regarder le film le transporteur 3