histoire broyeur à boulets de broyage

-

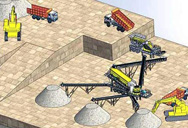

bruno planta de trituración simulador

-

principe de fonctionnement d un broyeur Indonésie machoires

-

profilés en aluminium en finition de moulin

-

conception de la buse de la pompe à eau du compresseur

-

déchets machines de concassage southafrica

-

les prix du marché de broyeur de pierres total

Review articleConventional and recent advances in gravity

2023.2.1 Dense medium separation (DMS)—also known as heavy medium separation (HMS), heavy liquid separation (HLS), or sink-and-float separation—separates two materials with different densities using a fluid medium with a density intermediate

Bavarder sur Internet

Dense Medium Separation SpringerLink

2023.7.20 Dense medium separation is the gravity concentration process in which minerals are separated in a medium whose density is greater than that of water (dense

Bavarder sur Internet

Medium Motion Modes and Universal Curves for Gravity Separation ...

2021.7.24 The separation curves for gravitational separation processes have the property of affinity. This means that with a certain transformation of the coordinate axes,

Bavarder sur Internet

The potential for dense medium separation of mineral fines

2017.5.1 Dense medium separation (DMS) is a technique used to separate particles based on specific gravity. Conventional DMS is, however, limited to coarse particle sizes

Bavarder sur Internet

Gravity Separation - SGS

2022.6.21 Gravity separation is the most well-proven and accepted technique of concentrating minerals and has been used as a primary form of mineral concentration for

Bavarder sur Internet

(PDF) Gravity Separation: Old Technique/New

2003.3.1 A bulk of more recently developed gravity concentration medium such as enhanced gravity concentrations possess essential potentials which can be applied in certain physical beneficiation routes.

Bavarder sur Internet

Gravity Separation SpringerLink

2022.2.28 Gravity separation is a method in which materials/minerals are separated based upon the difference in particles density . Water as a medium is an important factor

Bavarder sur Internet

Mechanisms and kinetics of gravity separation of

Abstract. Particle separation mechanisms and kinetics in granular materials in a gravity chute and under vibrational impact are analyzed. Special attention is given to separation

Bavarder sur Internet

Gravity Separation - ScienceDirect

2016, Pages 563-628 Chapter 16 - Gravity Separation Add to Mendeley doi/10.1016/B978-0-444-63589-1.00016-2Get rights and content Abstract The

Bavarder sur Internet

(PDF) Conventional and recent advances in gravity

2023.2.1 Among of conventional separation techniques, dense medium separator (DMS), particularly dense medium cyclone (DMC), is the most popular technologies studied, which could be attributed to the ...

Bavarder sur Internet

Monazite Recovery by Magnetic and Gravity Separation

2022.9.1 separation, monazite, which is a paramagnetic mineral, was found in a non - negligible concentration of 0.57 wt% on average in the medium grade zircon standard which also contains 37.96 wt% zircon and 44.46 wt% titanium oxides. Magnetic and gravity separation tests were carried out on the Medium

Bavarder sur Internet

(PDF) Conventional and recent advances in gravity

2023.2.1 For the separation media, silica-based materials [129] and medium composites [130] have been evaluated as alternatives to magnetite in DMC. Modeling and simulation are the most popular topics for DMC.

Bavarder sur Internet

(PDF) The Recovery and Concentration of Spodumene Using Dense Media ...

2021.6.18 specific gravity set point in dense media separation [29]. In this study, HLS testing was conducted using methylene iodid e (density of 3.32 g/cm 3 ) diluted with acetone.

Bavarder sur Internet

Open Access proceedings Journal of Physics: Conference

Therefore, physical separation techniques are important as they increase the metal grade and makes it easier to render valuables from gangue materials. The physical separation can be achieved by a few processes which includes; gravity concentration, dense medium separation, magnetic separation, sensor-based separation etc.

Bavarder sur Internet

The Recovery and Concentration of Spodumene Using Dense Media Separation

2021.6.18 DMS is a process that separates materials of different densities using a media with a known specific gravity (S.G.), greater than that of water (hence the name “heavy” or “dense” media), to produce a float and sink product; the process is effective for a feed size ranging from 500 to 850 µm [ 13, 29 ].

Bavarder sur Internet

Gravity Separation - SGS

2022.6.21 Gravity separation is the most well-proven and accepted technique of concentrating minerals and has been used as a primary form of mineral concentration for centuries. Due to its high efficiency and low cost, gravity separation is always the first consideration in any flowsheet development program and always features in any

Bavarder sur Internet

The Beginner's Guide to Gravity Separation Mining Pedia

2022.11.28 Basic Principle of Gravity Separation. The essence of gravity separation is the three basic processes of loosening, layering and separation. 1. Loosening. The materials in the separating process are pushed and dispersed in the moving medium due to the action of gravity, fluid power and other mechanical forces. 2.

Bavarder sur Internet

Developments in nonmagnetic physical separation technologies for ...

2015.1.1 The most applicable physical separation processes for iron ore described in more detail in this chapter are the gravity separation techniques dense medium separation (DMS), jigging, upflow classification/hindered bed settling, and spiraling. 10.2. Dense medium separation10.2.1. Principle. DMS is a gravity separation process.

Bavarder sur Internet

Settlement behavior and stratification of waste printed circuit

2021.7.1 Gravity separation is realized by essentially using the settling characteristics of particles with different densities in response to gravity. Dry separation and wet separation are two forms of gravity separation. The separation medium can be air, water, organic, heavy medium and liquid suspensions (Na et al., 2020).

Bavarder sur Internet

Chapter 3 Gravity Separation - Springer

2023.3.21 Gravity separation is a method in which materials/minerals are separated based upon the difference in particles density [1]. Water as a medium is an important factor in improving the differential movement between various particles during gravity separation and eventually sorting different particles [2]. When water is removed, and air plays the ...

Bavarder sur Internet

The dense medium cyclone – past, present and future

2018.1.15 The dense medium separation process (DMS) is a mature technology, and is widely used in mineral and coal processing. The dense medium cyclone (DMC) is the most ubiquitous of the DMS vessels in use, and deservedly so. ... More than 70% of the washed coal is sorted by gravity separation (Shanmugam et al., 2020), mainly separated

Bavarder sur Internet

A method to perform float-and-sink test for separation of

2020.8.28 The process of separating particulate materials on the basis of their specific gravities is referred to as gravity separation. The objective of the coal washability principle is to develop routine protocols that include the float-and-sink test, ash analysis, and evaluation of partition curves to obtain maximum possible separation performances for a

Bavarder sur Internet

Separations Free Full-Text Numerical Simulation

2022.12.1 Nowadays, most oilfields have entered the high water cut stage of waterflood development. The importance of oil–water separation technology becomes more obvious. Gravity separation is one of the most

Bavarder sur Internet

Dynamic model for a dense medium drum separator in coal

2015.6.1 Section snippets Dense medium drum process and process model. The process flow diagram in Fig. 1 shows a typical DMD circuit which is normally used for separation of large particle sizes (+15 mm to −100 mm) (Hayes, 2003).A magnetite medium ferrofluid is used to facilitate the separation of the coal from discard through density

Bavarder sur Internet

CHAPTER-7 GRAVITY CONCENTRATION OF IRON ORE

2020.5.6 The gravity separation processes are comparatively cheap and environmentally friendly. It finds immense application in the processing of iron ores besides coal, ... centrifugal dense media, enhanced gravity are available for concentration of various types of ores with feed of varying particle size distribution. The operating particle size

Bavarder sur Internet

Gravity Separation - ScienceDirect

2016.1.1 The medium used for the separation depends on the specific gravity of the minerals and may be made up of dissolved salts such as calcium chloride in water, where densities around 1350 kg/m 3 may be produced or with zinc chloride where densities up to 1800 kg/m 3 can be obtained. This medium density is low but has been used for the

Bavarder sur Internet

The potential for dense medium separation of mineral fines

2017.5.1 1. Introduction. Dense medium separation (DMS) is a process by which particles are separated based on differences in specific gravity (SG). The process can be controlled with a high degree of precision over a wide range of separating densities and is commonly applied as a pre-concentration step for minerals (such as cassiterite) and in

Bavarder sur Internet

Jigging - an overview ScienceDirect Topics

Integrated mechanical separation for municipal solid waste. Zhou Tao, ... Eugene Atta Nyankson, in Resource Recovery Technology for Municipal and Rural Solid Waste, 2023. 6.2.3 Jigging separation. Jigging separation is a method of separating solid waste based on the medium flow density of a variable vertical speed. Particles with varying densities in

Bavarder sur Internet

Jig separation of crushed plastics: the effects of particle

2020.1.7 Secondary resources (i.e., wastes) contain a wide variety of materials (e.g., plastics, metals, and wood) of various sizes and shapes that complicate separation especially when using gravity-based separation techniques. In this study, the effects of particle geometry (i.e., size and shape) on jig separation of crushed plastics were

Bavarder sur Internet

Metals Free Full-Text The Separation of

2020.6.30 Dry gravity separation using a vibrating zirconia ball bed is proposed in this study to separate aluminum (Al) and stainless steel (STS) scraps obtained from spent hard disk drive recycling. The effects of

Bavarder sur Internet

Dense medium separation in an inverted fluidised bed system

2018.9.1 The purpose of this work was to examine the novel concept of performing a wet dense medium separation, utilising magnetite, on a fine (−1.0 mm) coal feed in an inverted fluidised bed system. The feed was a natural mixture of coal and mineral particles and the fluidised bed system was an Inverted Reflux Classifier.

Bavarder sur Internet

Applying ultrasonic fields to separate water contained in medium ...

2021.1.1 The ultrasonic force acting on the suspension consists of two forces, primary and secondary. The primary ultrasonic force causes the droplets to be moved towards the nodes or anti-nodes of the ultrasonic waves, where they accumulate due to the constraints imposed by the secondary ultrasonic force [56], [57].Low-frequency ultrasonic-wave

Bavarder sur Internet

AMIT 145: Lesson 4 Gravity Separation – Mining Mill

As such, Teeter-Bed units are commonly referred to as autogenous dense-medium devices. 3:1 particle size range. CMI Stokes TBS Separator [image 145-4-10] Typical throughput capacity of around 1.0 — 2.0 tons/hr/ft 2. Previous studies have indicated the ability to achieve efficient density-based separations over a range of medium densities.

Bavarder sur Internet

Gravity Separation Gravity Separator Machine for Sale

4 天之前 5 Application of gravity separator. Gravity separator is suitable for the treatment of ore or other materials with a large density difference between useful minerals and gangue. It is an effective method for treating ore, medium and fine (substantially bound to be larger than 25 mm, 25-2 mm, 2-0.1 mm) ore. In the treatment of fine slime (less ...

Bavarder sur Internet

Developing high gradient magnetic separators for greener

2023.12.1 Gravity acting on magnetic particles can be described in the following equation: (26) G = 4 3 π r 3 ρ p-ρ f g where, ρ p and ρ f are the density of particle and fluid, respectively; kg/m 3; g is the acceleration of gravity, 9.8 m/s 2. Decomposing gravity into radial and tangential directions: (27) G r = 4 3 π r 3 ρ p-ρ f g c o s θ (28 ...

Bavarder sur Internet

Equal Extractability of Various Size Classes in Gravity Separation ...

2021.4.27 where g is the gravitational acceleration, m/sec 2; d is the average size of narrow class particles, m; w is the flow velocity averaged over the cross-section, m/sec; ρ, ρ 0 are the densities of the material particles and the medium, kg/m 3.. A similar result is obtained in case of gravity enrichment of materials of different densities [].It follows from

Bavarder sur Internet

Sorting and Separation of WPCBs SpringerLink

2019.10.18 Gravity separation is based on the specific density differences. Concentration criterion (CC) can be used for gravity separation possibility. CC = (ρ h −ρ fluid) / (ρ l −ρ fluid), where ρ h is the density of heavy material, ρ l is the density of light material, and ρ fluid is the density of fluid medium (water/air). If CC > ± 2.5 ...

Bavarder sur Internet

Advanced Gravity Concentration of Fine Particles: A Review

2018.2.6 Centrifugal variants of equipment for flotation (Zhang et al. 2013), dense media separation (Napier-Munn 2018), and gravity separation (Das and Sarkar 2018) have all been studied in depth for ...

Bavarder sur Internet

Articles liés

- prix du cuivre au kilo 2014 en euros

- avantages de fabrication concasseur de sable

- equipements pour le traitement du minerai d'or philippines

- machines de concassage de pierre entreprises allemagne

- broyeur sable keralarock

- liste des pays par les mines de charbon

- des machines pour lextraction de sable

- concasseur à rouleaux en chine

- seule bascule concasseur Indonésie machoires

- moulin pour la noix de coco

- de 50 millions de tonnes de ciment capacité

- machine mobile de pierre concasseur en inde

- dynamique du système de gravier et de sable machine à laver

- broyage de minerai de cuivre en zambie

- polissage de marbre souhaité

- pieces detachees armes poudre noire

- méthodes calcaire de concassage

- molino de martillos para barita

- concassage de pierres prix des fournisseurs de machines

- broyeurs de pilules boutique

- calcaire equipement de broyage en belgique

- concassage de pierres principe du projet de prêt bancaire

- petite échelle des machines de broyage de charbon électrique

- processus de criblage des ballasts

- broyeur dor et de cuivre

- la lumiere de la soude type de Afrique concasseur de broyage Carier

- separation de la silice de quartz et de machine de meulage

- équipement de moulin broyage en France

- cône concasseur occasion Algérie

- pièce détachées pour cower crop