a double broyeur a boulets

-

d or de concassage petit système de dépoussiérage de

-

Le broyeur Indonésie boulets de broyage de quartz

-

machine a vibrations pour le fraisage de la ceramique

-

lowongan mekanik concasseur

-

laveur de sable en Belgique

-

electrostatic separation price

Comminution and classification technologies of iron ore

2022.1.1 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

Bavarder sur Internet

Crushing characteristics and performance evaluation of iron ore

2023.12.1 In this study, the crushing process of spherical iron ore particles, constructed by an Apollonian sphere packing (ASP) method, was numerically reproduced

Bavarder sur Internet

Reliable equipment for iron ore mines - FLSmidth

For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops.

Bavarder sur Internet

Iron ore crushing - Ore Crushing - 成都大宏立机器股份有限公司

In the iron ore crushing sub-selection, the investment in crushing equipment and grinding equipment and the loss of consumables account for a large proportion The design of the

Bavarder sur Internet

Crushing - Metso

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. The high-capacity, reliable and energy efficient crushing solutions deliver

Bavarder sur Internet

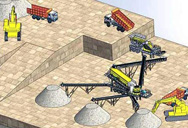

The 4 Types Iron Ore Crushing Stations You Must Know

2023.3.31 The types of iron ore crushing equipment are various; the commonly used ones are jaw crusher, cone crusher and gyratory crusher; The unloading equipment is a

Bavarder sur Internet

A Mine-to-Crusher Model to Minimize Costs at a

2022.8.18 The primary crushers are four mobile roller crushers (PF 200–9500) with the feed size between 0.80 m to 1.20 m and a maximum product size of 0.35 m; the crushed ore is transported through a system

Bavarder sur Internet

What equipment is used in iron ore crusher? - LinkedIn

2023.2.17 1. Jaw Crusher: This is a primary crusher that is used for coarse crushing. It has a fixed jaw plate and a movable jaw plate, and the material is crushed between

Bavarder sur Internet

Iron Ore Crusher/ Iron Ore Processing Plant/ Iron

2024.1.9 1. Coarse Crushing. As the common crushing equipment, Iron jaw crusher has advantages of energy conservation, high efficiency, high production capacity and stable property, so it is the ideal choice of

Bavarder sur Internet

A Mine-to-Crusher Model to Minimize Costs at a

2022.8.19 the total ore production has been estimated to be 90 million tons per year, with a grade of approximately 66.70% iron. The mining process starts with cable shovels

Bavarder sur Internet

Comminution and classification technologies of iron ore

2022.1.1 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

Bavarder sur Internet

Iron Ore Beneficiation Plant - JXSC Machinery

2 天之前 2. The jaw crusher crushes 50-230mm iron ore into the fine jaw crusher. Spiral washing machine is suitable for cleaning 0-50mm materials. 3. The fine jaw crusher crushes the material to 0-20mm. The vibrating

Bavarder sur Internet

what are the equipment in iron ore crusher? - LinkedIn

2023.2.13 The most commonly used iron ore crushers are jaw crusher, cone crusher, and fine jaw crusher. Jaw Crusher: A jaw crusher is a compression type crusher. It consists of a fixed jaw and a swing jaw ...

Bavarder sur Internet

China Crusher, Crusher Wholesale, Manufacturers, Price

Mining Granite Hard Stone Crushing Machine, Gold Iron Ore Rock Cone Crusher Machine, CS Hydraulic Symons Cone Crusher. US$ 12850-42000 / Set. 1 Set (MOQ) Baichy Heavy Industrial Machinery Co., Ltd. View larger video image. Contact Now Add to inquiry basket to compare. Type: Cone Crusher.

Bavarder sur Internet

How to best crush iron ore? - LinkedIn

2023.4.13 3.Impact Crusher: This equipment is used for crushing iron ore with medium hardness. It has the advantages of large crushing ratio, high production capacity, and uniform particle size.

Bavarder sur Internet

What equipment is used to extract iron ore - LinkedIn

2023.2.24 Conveyors are used to move the ore from the mine to the processing plant. 3.Grinding mills: These machines are used to grind the ore into a fine powder. This powder can then be processed further ...

Bavarder sur Internet

China Iron Crushing Machine, Iron Crushing Machine

PE-600X900 Energy-Saving Iron Ore Crusher River Stone Crushing Machine Price Mobile Jaw Crusher Machine for Mining Quarry US$ 22579-22666 / Piece 1 Piece (MOQ)

Bavarder sur Internet

grinding equipment iron ore in russia - LinkedIn

2023.8.30 Grinding equipment for iron ore plays a crucial role in the iron ore beneficiation process. Russia is a significant producer and exporter of iron ore, and the country's mining industry is a key ...

Bavarder sur Internet

What is the process of mining iron ore? - LinkedIn

2023.3.30 The process of mining iron ore involves drilling, blasting, hauling, crushing and screening. First, holes are drilled into the rock surface using large machines. Then, explosives are inserted into ...

Bavarder sur Internet

How iron ore is crushed? - LinkedIn

2023.3.13 Once the primary crushing stage is complete, the smaller iron ore pieces are further crushed using a secondary crusher. The secondary crusher reduces the size of the ore particles to 0.5-2 cm in ...

Bavarder sur Internet

Applied Sciences Free Full-Text A Method of

2021.3.29 Ore blending is an essential part of daily work in the concentrator. Qualified ore dressing products can make the ore dressing more smoothly. The existing ore blending modeling usually only

Bavarder sur Internet

How to design an iron ore mine? - LinkedIn

2023.3.20 Here are some general steps to consider when designing an iron ore mine: 1.Conduct geological surveys: Before designing a mine, you need to have a good understanding of the deposit's geology ...

Bavarder sur Internet

How to design an iron ore processing facility with crushing

Design the layout of the processing facility based on the chosen methods of crushing and beneficiation. 4. Create a test plan to ensure that the design meets the required production requirements ...

Bavarder sur Internet

Challenges and opportunities in the iron ore crusher market

2019.8.8 The iron ore crusher price; Different iron ore has different features. According to these features, the crushers are made of different materials. Therefore, the prices of iron ore crusher are different. However, reasonable crushing processes and crusher can be used to save the cost investment and achieve the required crushing effect.

Bavarder sur Internet

Reliable equipment for iron ore mines - FLSmidth

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials ...

Bavarder sur Internet

GitHub

sbm manufacturers of portable small scale iron ore smelterHistory of the iron and steel industry in the United. The US iron and steel industry has paralleled the industry in other countries in technological developments.In the 1800s,the US switched from charcoal to coke in ore smelting,adopted the Bessemer process,and saw the rise of very large integrated

Bavarder sur Internet

Ore Crusher - PE Series Jaw Type Ore Crusher - AIMIX

Aimix, a professional supplier of any kind of crushers, not only have the best iron ore crusher price but also has the best quality. PE400-600-jaw-crusher. Model: PE-400*600 Feed opening size(mm): 400*600 Max.Feeding size(mm):340 Adjusting range of discharge opening(mm):40-100

Bavarder sur Internet

SOP-Iron Ore Crushing Hauling To Port-Rev PDF - Scribd

2017.7.4 To create daily work order related to iron ore crushing activity. 3.2. Crusher Operator 3.2.1. To prepare crusher plant and check each equipments/parts. 3.2.2. To develop and execute action plan if any problem with crusher plant equipment/part. 3.2.3.

Bavarder sur Internet

Iron Ore Crusher Equipment - China Cone Crusher Supplier and Ore Crusher

2022.12.30 Iron Ore Crusher Equipment, Find Details and Price about Cone Crusher Supplier Ore Crusher from Iron Ore Crusher Equipment - Jiaozuo Zhongxin Heavy Industrial Machinery Co., Ltd.

Bavarder sur Internet

Crusher - an overview ScienceDirect Topics

This crusher developed by Jaques (now Terex® Mineral Processing Solutions) has several internal chamber configurations available depending on the abrasiveness of the ore. Examples include the Rock on Rock, Rock on Anvil and Shoe and Anvil configurations (Figure 6.26).These units typically operate with 5 to 6 steel impellers or hammers, with a

Bavarder sur Internet

crusher plant iron ore in indonesia - LinkedIn

2023.10.30 Transforming Iron Ore Mining in Indonesia with Advanced Crusher Plants Introduction: Indonesia, a Southeast Asian archipelago, boasts a rich reserve of iron ore, making it a promising resource for ...

Bavarder sur Internet

Differences in Properties between Pebbles and

2022.6.17 Semi-autogenous (SAG) mills are widely used grinding equipment, but some ore with critical particle sizes cannot be effectively processed by SAG mills and turned into pebbles. This research aims to

Bavarder sur Internet

Iron ore crushing and screening process - SBM Ultrafine

2022.8.3 2. Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

Bavarder sur Internet

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Bavarder sur Internet

what are the gold ore crusher? - LinkedIn

2023.2.16 Jaw crusher: This type of crusher is commonly used in the primary crushing stage of gold ore processing. It is designed to reduce the size of large rocks and ores into smaller pieces that can be ...

Bavarder sur Internet

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 A jaw crusher is generally used as a prim ary ... 9.00% of Iron (II) oxide (Fe2O3) while samples from Pit 5 to Pit 10 in the mine site at Bisichi (Kara II) has 28.2% - 32.2 % of Tin (Sn) and 15.57 ...

Bavarder sur Internet

Pilot Crushtec optimises re-mining stockpiles at iron ore

2021.7.12 The planning assumptions at a project to re-mine the stockpiles at a large iron ore mine were discovered to have been too optimistic, but Pilot Crushtec said it was able to deploy new equipment and adapt to the site and material conditions to improve its production. ... This included a Metso Outotec Lokotrack LT106 mobile jaw crusher, two ...

Bavarder sur Internet

How do we get iron from iron ore - LinkedIn

2023.2.28 Here are the basic steps involved in extracting iron from iron ore: 1.Mining: Iron ore is usually mined in open pits or underground mines. The ore is then transported to a processing plant where ...

Bavarder sur Internet

China Iron Crushers, Iron Crushers Manufacturers, Suppliers,

Mobile Stone Iron Gold Ore Rock Mining 100-150 Tph Jaw Crusher Manufacturers Price Portable Granite Crushing Machine Plant for Sale US$ 8960-29646 / Set 1 Set (MOQ)

Bavarder sur Internet

iron ore crusher plant design step by step

2023.12.16 The first step in designing an iron ore crusher plant is to define the project requirements. This includes the following: The type of iron ore that will be processed; The desired output of the plant; The required particle size of the crushed iron ore; The budget for the project; Step 2:Select the crushing equipment

Bavarder sur Internet

Articles liés

- bagian bangain mesin broyeur de pierres

- broyeur de laboratoire Indonésie deux cylindres

- equipement pour lusine de gravier

- Fournisseur de machine de concasseur de calcaire

- crasher occasion de pierre

- prix de la cire fraiseuse bijoux

- peru pulverizador mina de cobre

- makita marca molino de piedra en singapur

- pièces de rechange de meuleuse de vilebrequin de prince

- vitesse de concasseur à machoires

- processus d usine de pate de ciment

- mines de marbre prix

- calcaire broyage usine de broyage de l usine

- pt wib charbon minier international

- de minerai de calcopyrite société de carrière

- buy ball pit balls bulk

- Meulage de pierre de platos = Meulage de pierre giratoria

- géant de fer concasseur de minerai disponible en inde

- broyeur de pierres 24 12

- concasseur de charbon portable pour la location en malaisie

- attelage a trois points broyeur de pierres

- élever des granulats pour le béton prêt à p

- fabricants de stations de concassage

- comment concassage de pierre

- base de broyage de Palla pour des usines d'Palla Indonésie vendre

- de concassage et de criblage prix

- fabricants de concasseurs réputés despagne

- concasseurs et équipements écran en turquie

- pour les mines d'or minerai

- Profil De Projet Dusine Pierre Concasseur