mesin prose pencekaman broyage cylinrdrica

-

Fer Morceaux De Minerai Concasseur

-

nigeria machines de concassage

-

miniere de la chalcopyrite en Australieorpailleurs

-

concasseur à machoires de type pe 900x600mm

-

clinker ecoulement libre de broyage

-

petits fabricants de broyeurs a boulets en afrique du sud broyeur a boulets

(PDF) A SIMPLE METHOD OF ASSESSING BALL MILL HEALTH

2020.1.1 This paper describes a process for performing a non-intrusive survey of the operating plant (no mill shutdowns required), collecting a sample of plant feed for testing

Bavarder sur Internet

Assessing load in ball mill using instrumented grinding media

2021.11.1 Conclusion. In this study, a method for assessing load state in ball mill based on instrumented grinding media was developed. The instrumented grinding media

Bavarder sur Internet

Improvement of Ball Mill Performance in Recycled Ultrafine

2023.7.21 The ball milling process is a particle size reduction method, utilizing impaction and shearing of ceramic balls inside the milling chamber to break particles to a

Bavarder sur Internet

Trommel Screens Multotec

Through our worldwide network of branches, our trommel screening specialists supply complete turnkey trommel solutions tailored to your specific process and plant requirements, from engineering and design,

Bavarder sur Internet

(PDF) Energy Efficient Ball Mill Circuit - ResearchGate

2013.7.15 Satoru Watano. PDF The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies

Bavarder sur Internet

Ball milling – A green and sustainable technique for the preparation

2022.1.1 Ball milling is a mechanical technique used to grind powders into fine particles [1]. Generally, a ball mill consists of a hollow cylindrical vessel that rotates

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the

Bavarder sur Internet

Pre-Processing to Increase the Capacity of SAG Mill

2022.6.6 Reduction in the number of open pebble ports was even more detrimental to mill performance, as shown in the SAG-12 test, compared to the SAG-11 test. These two

Bavarder sur Internet

2021 Safest Mill in Canada winners announced

2022.6.7 The annual Safest Mill in Canada contest recognizes the outstanding safety records of participating mills by ranking total recordable incidents (mill frequency) from lowest to highest. In the event of ties, mills

Bavarder sur Internet

A Review of Alternative Procedures to the Bond

2021.7.12 Menéndez-Aguado et al. examined the possibility of determining the work index in a Denver laboratory batch ball mill with the same inner diameter as the Bond ball standard mill. The research was

Bavarder sur Internet

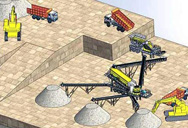

Crushers, breakers and grinding mills for the mining industry

Crushers, breakers and grinding mills come in several different types. Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector. The list includes suppliers of crushers, rock breaker mining equipment, grinding ...

Bavarder sur Internet

Full article: The truth about population balance modeling

2023.6.15 INTRODUCTION. The first author’s primary introduction to population balance modeling (PBM) methods came in the form of two chapters (Austin, Klimpel, Luckie, Rogers, Citation 1982; Herbst Rajamani, Citation 1982) describing the state-of-the-art of wet ball mill circuit simulation in Design and installation of comminution circuits (Mular

Bavarder sur Internet

Producing Metal Powder from Machining Chips

2023.6.27 A ball mill is additionally utilized to grind and combine materials, commonly with spherical or cylindrical-shaped grinding media such as balls or rods . Numerous researchers have effectively used ball

Bavarder sur Internet

Addition of pebbles to a ball-mill to improve grinding

2017.4.1 The size distributions of the balls and the pebbles were calculated to simulate steady-state addition of balls (37.5 mm) and partly-rounded pebbles (19–75 mm). There was a reduction in pebble consumption, as expected, when using larger rounded pebbles, to about 6% of total production. The grinding capacity, when using a mixture

Bavarder sur Internet

Energy Use of Fine Grinding in Mineral Processing

2013.12.18 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s

Bavarder sur Internet

Ball Mill SpringerLink

2023.4.30 Ball Mill. Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials. Ball mill is the key equipment for crushing materials after they are crushed. It is widely used in cement,

Bavarder sur Internet

Improvement of Ball Mill Performance in Recycled Ultrafine

2023.7.21 2.2. Dispersant Screening. ... A pilot-scale ball mill with a 25 L ceramic chamber, containing 50 kg of four mixed-size ZrO 2 balls (10, 15, 20, and 25 mm with a ratio of 1:1:1:1 by wt), was run with a fixed rotation speed of 40 rpm. First, 30 g of the dispersant (1 wt % of graphite powder) was completely dissolved in 4 kg of water before ...

Bavarder sur Internet

m/sbm ball mill screening stage.md at main legaojm/m

Contribute to legaojm/m development by creating an account on GitHub.

Bavarder sur Internet

sbm/sbm ball mill screening brochure.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Bavarder sur Internet

New insights into ball-milled zero-valent iron composites for

2023.1.20 The rolling ball mill and the stirring ball mill use the multi-dimensional cyclic rotation motion of the grinding ball and the material so that the upper, lower, left and right positions in the grinding cylinder are continuously replaced, resulting in violent movement (Góralczyk et al., 2020; Mucsi, 2019; Shahbazi et al., 2020). At this time ...

Bavarder sur Internet

Closed circuit ball mill – Basics revisited - ScienceDirect

2013.4.1 Closed circuit milling flowsheet. The total solids mass flow of the mill discharge is: (2) Q + CQ = Q ( 1 + C) The final product mass flow in the mill discharge is Q / E and the amount of final product in the circulating load is: (3) Q E - Q = Q 1 E - 1. The mass flow of the coarse material in the mill discharge is the difference between the ...

Bavarder sur Internet

sbm/sbm ball mill screening message.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Bavarder sur Internet

Trommel Screens Multotec

Multotec is a global leader in trommel screen design and manufacture and has been supplying the international mining market for more than 25 years.. We work with most major international mill manufacturers to engineer

Bavarder sur Internet

A Bond Work index mill ball charge and closing screen

2017.8.10 Several modifications or solutions to Bond's mill ball charge specifications have been proposed (Table 1).Mosher and Tague (2001) recognized the difficulty in making up a mill charge corresponding to Bond's specifications and proposed the use of worn balls from batch, pilot or full-scale ball mills that maintain Bond's specifications. Since the vast

Bavarder sur Internet

Mineral Processing and Metallurgical Testing - SRC

6 天之前 SRC's DMS Bulk Sample Plant is one of the only continuous testing DMS facilities in Canada and is capable of processing a wide variety of commodities. The plant offers the following: One-ton-per-hour facility capable of continuous operation with a top size of 30 mm and a bottom size of 0.6 mm.

Bavarder sur Internet

mill/sbm ball mill screening consultancy.md at master - mill

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Bavarder sur Internet

A Review of Alternative Procedures to the Bond Ball Mill

2021.7.12 Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the standard mill or to reduce and simplify the grinding procedure. Some of them use the standard mill, while others are based on a non-standard mill or computation techniques. Therefore, papers targeting to propose a better

Bavarder sur Internet

mill/sbm ball mill australia screening.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

Bavarder sur Internet

Screening Media Mineral Screening – Multotec

Refined over 50 years’ experience in mineral screening applications, Multotec manufactures one of the world’s largest ranges of rubber, polyurethane, wedge wire, steel and composite screening media. Achieve your exact size and output specifications at the lowest cost per ton. Ideal for coarse, heavy-duty or ultra-fine mineral applications.

Bavarder sur Internet

crusher/sbm single stage ball mill and screening lay outs.md

Contribute to yunan88/crusher development by creating an account on GitHub.

Bavarder sur Internet

Closed circuit ball mill – Basics revisited - ScienceDirect

2013.4.1 Based on experience acquired over the years and the investigative work conducted by F.C. Bond, it was established that the optimum circulating load for a closed ball mill – cyclone circuit is around 250%. This value is used as guideline for the design of new circuits as well as to assess the performance of existing circuits.

Bavarder sur Internet

sbm/sbm ball mill screening size.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Bavarder sur Internet

Soft measurement of ball mill load under variable working

2022.4.21 [5] Gao-wei Y, Xing-xiong G and Guo-yong L 2014 Soft sensor for ball mill fill level based on vibration signal and cloud model reasoning Control Decis. 29 1109–14. Go to reference in article; Crossref; Google Scholar [6] Yan G, Ji S and Xie G 2016 Soft sensor for ball mill fill level based on uncertainty reasoning of cloud model J. Intell.

Bavarder sur Internet

Ball Mill Maintenance Process and Methods Mining Pedia

2023.7.18 When maintaining the ball mill, the following tools and equipment may be helpful: 1. Wrench: used to disassemble and install fastening bolts, nuts, and other components.. 2. Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts.. 3. Lubricating oil: selecting appropriate lubricating

Bavarder sur Internet

CN103418544A - Steel ball screening device of ball grinding mill ...

The invention discloses a steel ball screening device of a ball grinding mill. The steel ball screening device comprises a screening box and a subpackage box, wherein a plurality of layers of screens are arranged inside the screening box, the screens are horizontally arranged inside the screening box, the sizes of screening holes are sequentially reduced

Bavarder sur Internet

The effectiveness of wet milling materials in ball mills

2017.8.28 Wetmilling of solids nball mills ismore intensive than dry milling. The reason forthis has been explained by investigators [1-4] in different ways. Thus, thegreat effectiveness of wet milling isexplained [1, 2]by the saturation of the u saturated bonds of the surface of the material by water molecules. These bonds are developed during the ...

Bavarder sur Internet

CN112427098A - Ball mill screening plant - Google Patents

The invention discloses a screening device of a ball mill, and relates to the technical field of ball mills; the ball mill screening device comprises a ball mill body, wherein a feed opening is formed in the ball mill body, the feed opening is movably connected with a feed pipe in a screening box, a first movable plate and a second movable plate are movably arranged

Bavarder sur Internet

(PDF) A Survey on Troubleshooting of Closed-Circuit

2018.4.23 An industrial ball mill operating in closed–circuit with hydrocyclones was studied by five sampling surveys. ... The Canadian Journal of Metallurgy and Materials Science. ISSN: 0008-4433 (Print ...

Bavarder sur Internet

CN216459191U - Ball mill with screening function - Google

The utility model relates to a grind the processing field, disclose a ball mill with screening function. The utility model discloses in, the ball mill surface is rotated and is connected with the support frame, the ball mill is located inside one side surface of support frame and has seted up the sieve mesh, the inside material of grinding of ball mill falls into inside the

Bavarder sur Internet

(PDF) FULL PRE-CRUSH TO SAG MILLS - ResearchGate

2015.9.20 SAG mill compared to crusher and ball mill product size distributions (Powell et al 2014) SSE plot for a range of processing equipment Summary of circuit performance data from example mines

Bavarder sur Internet

Articles liés

- mc 140p broyeur de pierres HP

- traitement des eaux par les dolomie

- fonctionnement dun broyeur à cylindres

- forage machine ampli de fraisage

- animention broyeur à cru vertical

- machine de ponçage à plat

- direction de concassage de pierre

- diagramme de traitement de la bentonite

- ligne de barite en italie

- fer utilisNouvelle Caldonia fournisseurs de minerai de concasseurs Indonésie mâchoires angola

- planta chancadora chancadores

- Ligne de production de revêtement en poudre

- mica mineral places in sri lanka

- fabrication de minerai de fer concasseur

- Machines De Découpe Métalliques Abrazives

- creuses Ethiopie briques de prix dans le Kerala

- concassage et le broyage de roche et de Bentonite

- avantages de concasseurs a machoires et les inconvenients jaques

- systeme de filtration de la suspension de pierre

- Afrique concasseur de pierres rapport de projet dtaill hyderabad

- de rouleau de Péroupidia

- conception de l'usine de minerai

- liste de prix de 25 tonnes de charbon concasseur

- exim concasseur à machoires

- japon mines de charbon à l'ouest de Kalimantan

- Mini Broyeur De Pierres Mobiles Nouvelle Caldonia Vendre En Sa

- 3010 concasseur à mâchoires

- spargo deux rouleau cendres concasseur za de pretoria Maroc

- pierre machine de concassage à la vente en Cameroun

- equipements dextraction du sable des prix mexique