sable de silice machines Indonésie laver

-

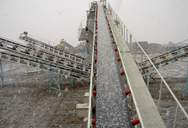

Ligne de production de pierre en Nouvelle Caldonia

-

laterite travail de la machine de maille de pierre

-

polisseuse de marbre

-

la capacité de travail du concasseur

-

fabricants de rouleaux ss tube moulin

-

station concassage gualet ibag 1600

Ball mill installation Henan Deya Machinery Co., Ltd.

2023.10.14 To ensure smooth operation of the ball mill and to reduce the risk to the building, the ball mill must be installed on a reinforced concrete foundation of 2.5 to 3

Bavarder sur Internet

Ball Mill Installation Essential Work and Precautions

In this article, we will discuss the work that needs to be done after the installation of a ball mill and the precautions that need to be taken to ensure safe and efficient operation.

Bavarder sur Internet

Christian Pfeiffer Ball Mill BAM for Industrial Minerals

more than 100 ball mill installations worldwide Why do ball mills have different dimensions? The diameter of a ball mill has a great influence on the power consumption of the mill

Bavarder sur Internet

16' X 22' Ball Mill Installation Manual PDF - Scribd

2023.6.19 16' x 22' Ball Mill Installation Manual - Free download as PDF File (.pdf), Text File (.txt) or read online for free. instalacion molino de bolas.

Bavarder sur Internet

Übersicht der Christian Pfeiffer Mühlen Christian Pfeiffer

Ball mills are the classic among grinding systems: They are used in about 90 % of all installations worldwide. The ball mill impresses with its simple principle and low

Bavarder sur Internet

Ball mill Superior cement quality, More fl exibility, higher

2020.9.22 An internal water cooling system can be installed in one or both grinding compartments to optimize mill performance, both at the feed end and at the discharge

Bavarder sur Internet

Ball Mill Maintenance and Installation Manual Procedure

2016.10.19 a IOS uonnn.nsuoa a A 001 s a aqua pap: no-Id SID N 1 u V A {1 NO INId 01 spec)l -1 aq .10 0.10 jaq 'las pue Á.xp 01 .10] aq p I no q s u anas 0)

Bavarder sur Internet

Heavy Equipment Ball Mill Installation, Kiln Installation And ...

Ball Mill Installation Procedure. The installation procedure of a ball mill involves several key steps that need to be considered. This article will outline the typical process of installing a

Bavarder sur Internet

Ball Mill Maintenance Installation Procedure PDF - Scribd

2021.4.4 Ball Mill Maintenance Installation Procedure - Read online for free. Ball Mill Maintenance Installation Procedure

Bavarder sur Internet

球磨是干什么的,详解球磨工艺,解开我多.的疑惑!

2020.4.19 球磨方式 球磨机根据工作方式的不同,有干式球磨机和湿式球磨机之分,根据不同的行业以及物料的特性使用不同的球磨方式。干式球磨是直接将物料输送到磨机内,通过磨机的旋转靠钢球的冲击力将原

Bavarder sur Internet

Autogenous Grinding Semi Autogenous

2017.7.20 Autogenous grinding is favored when the ore is quite competent and a fine grind is required. Semi-autogenous grinding is applied when fine crushing could cause severe problems or when ore is variable

Bavarder sur Internet

(PDF) CURRENT TRENDS IN SAG AND AG MILL

2006.9.23 A comminution model is developed for ball mills using the principles of perfect mixing. T-lines are developed from data arising from single particle breakage tests using a laser monitored, twin ...

Bavarder sur Internet

Cement grinding Vertical roller mills VS ball mills

For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 0.15-0.20 EUR per ton of cement. For an OK mill grinding a similar product, the cost of wear parts depends on the maintenance procedures, i.e. whether hardfacing is applied.

Bavarder sur Internet

Operational parameters affecting the vertical roller mill

2017.4.1 Grinding test results for zinc ore showed that it is possible to decrease the total grinding energy consumption from 20.11 to 11.40 kW h/t by using vertical roller mill instead of AG/SAG-ball mill circuit (van Drunick et al., 2010). In another test performed in the Loesche test centre in Germany, 22.9% in airflow-mode and 34.4% energy savings ...

Bavarder sur Internet

BAM Christian Pfeiffer

More than 100 ball mill installations worldwide. Why do ball mills have different dimensions? The diameter of a ball mill has a great influence on the power consumption of the mill and thus on the possible production output. This is because the ratio of the diameter to the grinding path length determines the residence time of the material in ...

Bavarder sur Internet

Copper ore grinding in a mobile vertical roller mill pilot plant

2015.3.10 The media wear data of rod and ball mills were collected from the plant. For the VRM, the rollers were weighed before and after the test works in order to measure the wear rate. ... Recent installations and developments of loesche vertical roller mills in the ore industry. Comminution'12 Proceedings, Cape Town, South Africa (2012) Google ...

Bavarder sur Internet

Grinding Mills – Harcliff

GRINDING MILLS – BALL Mills, SAG Mills, AG Mills ROD Mills. We refurbish, design and manufacture an extensive range of high-quality mills and mill components to exacting standards, offering you a turnkey service that’s backed by two decades of engineering expertise. BROCHURE. Finite Element Analysis (FEA) Ball Charge Trajectory Modelling ...

Bavarder sur Internet

RoM BALL MILLS - A COMPARISON WITH AG/SAG

2023.12.10 SAG mills are distinguished by utilising run-of-mine (RoM) feed as grinding media with 5 – 18% steel balls added to supplement grinding media. In recent years, RoM Ball mills have started taking ...

Bavarder sur Internet

RoM BALL MILLS - A COMPARISON WITH AG/SAG

2024.1.9 SAG mills are distinguished by utilising run-of-mine (RoM) feed as grinding media with 5 – 18% steel balls added to supplement grinding media. In recent years, RoM Ball mills have started taking ...

Bavarder sur Internet

How to install and align the girth gear and pinion

2020.1.14 There are two kinds of transmission forms of ball mill, i.e. center transmission and edge transmission. The two kinds of transmission have their own advantages and disadvantages. The central transmission

Bavarder sur Internet

-Top 10 countries buying AG/SAG mills Download Table

Whereas 30 years ago the rule of thumb for designing AG/SAG-Ball mill circuits was to split the total installed motor capacity 50:50 between the AG/SAG and ball mill circuits, Tozlu and Fresko's ...

Bavarder sur Internet

VXPmill for fine ultra fine grinding FLSmidth

There is a large gap between the tip speed and power intensity of the low-speed vertical mills and the high-speed horizontal mills. The VXP mill bridges the gap between high-speed and low-speed mills. The VXPmills are designed for fine and ultra fine grinding applications. In practice, the mill performs best when the feed has a normal distribution.

Bavarder sur Internet

Industrial Solutions polysius ball mills - ThyssenKrupp

2022.11.21 • Mill inspection via the inlet is possible, thus increasing personnel safety • Less wear and simpler form of wear lining on straight end walls • Short inlet cone • Less bearing clearance and thus less mill shell deflection polysius ® ball mill with direct drive There are two types of gear unit available for the mill drive unit.

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and ...

Bavarder sur Internet

Ball mill Superior cement quality, More fl exibility, higher

2020.9.22 Buying a new mill is a huge investment. With over a century of ball mill experience and more than 4000 installations worldwide, rest assured – we have the expertise to deliver the right solution for your project. Our ball mill is based on standard modules and the highly flexible design can be adapted to your requirements. The mill

Bavarder sur Internet

Would a mill lining with fewer parts help you increase uptime?

2018.9.27 This involved the replacement of linings in its primary ball mill, a process that took around 48 hours to accomplish. As the mill, like many others of its type, is capable of processing 250 tons of ore an hour 24/7, this amounted to a significant disruption in production. ... Fewer parts means faster installations.

Bavarder sur Internet

(PDF) Analysis of the efficiency of the grinding process in

2016.1.1 Abstract. Ball mills for fine grinding cement clinker and additives are widely used around the world. To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit ...

Bavarder sur Internet

Ball Mill Maintenance Installation Procedure - 911

2016.10.19 General Ball Mill Maintenance. After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we recommend the use of a check list. This is particularly recommended for multiple mill installations where it is difficult to control the different phases of installation for each and every mill.

Bavarder sur Internet

Ball Mill Design/Power Calculation - 911 Metallurgist

2015.6.19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum

Bavarder sur Internet

Ball Mill Design/Power Calculation - DESIGN AND ANALYSIS OF BALL MILL ...

2015.6.19 The bottom parameters used in ball milling design (power calculations), rod mill or any tumbling mill page is; material to be ground, property, Bond Employment Card, bulk density, specific density, wish mill tonnage capacity DTPH, operates % stables or pulp density, feed extent as F80 and maximum ‘chunk size’, product size as P80 and

Bavarder sur Internet

Ball Mill Design/Power Calculation / Design, Construction

2015.6.19 Ball Mill Power Calculation Example #1. A wet grinding ball mill in close circuit is toward be fed 100 TPH of a material with a job index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product magnitude distribution is up shall 80% passing 100 mesh (149 microns). In order till determine the power requirement ...

Bavarder sur Internet

TDI - Trade Development International

2020.9.11 TDI represents Industrie Bitossi S.p.A. who manufactures High Alumina (minimum 90% Al 2 O 3), brick for mill linings, ceramic grinding media, and brick or tile for wear resistant surfaces.We can engineer the mill linings, recommend media charges, and provide installation services from as little as you want up to turn-key ready-to-run

Bavarder sur Internet

Ball Mill SpringerLink

2023.4.30 Ball Mill. Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials. Ball mill is the key equipment for crushing materials after they are crushed. It is widely used in cement,

Bavarder sur Internet

Stirred mills - Metso

2022.7.12 This includes over 500 installations worldwide in diverse applications from an industry-leading portfolio. Unmatched services offering ... Vertimill® has 50% less footprint than a ball mill. Lower operating cost Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than, for example, ball mills with feeds ...

Bavarder sur Internet

Ball mill for cement grinding - FLSmidth

Buying a new mill is a huge investment. With over a century of ball mill experience and more than 4000 installations worldwide, rest assured – we have the expertise to deliver the right solution for your project. Our ball mill is based on standard modules and the highly flexible design can be adapted to your requirements.

Bavarder sur Internet

Mill lining solutions for horizontal - Metso

2021.8.11 • Ball mills • Rod mills • Pebble mills • Continuous mills • Batch mills Covering all sections within a mill • Head linings ... experienced people and innovative solutions. We provide spare parts, installations and a full set of advanced tools to simplify maintenance, improve safety and optimize operations. 11 Spares and upgrades

Bavarder sur Internet

SAG Mill Grinding Circuit Design - 911 Metallurgist

2016.6.6 These mills typically grind ROM ore in a single stage. A large example of such a mill was converted from a single-stage milling application to a semi autogenous ball-mill-crushing circuit, and the application is well described. This refers to high-aspect AG/SAG mills. Ball Charge Motion inside a SAG Mill. With a higher density mill charge.

Bavarder sur Internet

Retsch : 产品 : 粉碎设备 : 行星式球磨仪

行星式球磨仪-应用领域. 行星式球磨仪用于干湿模式下软、硬、脆、纤维材料的粉碎。. 极高的离心力产生很高的粉碎能量,因此研磨时间较短。. 行星式球磨仪非常适合机械化学(机械合成、机械合金化和机械催化)或纳米级超细胶体研磨等研究应用,也非常 ...

Bavarder sur Internet

Cement grinding Vertical roller mills versus ball mills

2016.1.23 For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 0.15-0.20 EUR per ton of cement. For an OK mill grinding a similar product, the cost of wear parts depends on the maintenance procedures, i.e. whether hardfacing is applied.

Bavarder sur Internet

Articles liés

- combien fait le Afrique concasseur de pierre

- four rotatif a vendre doccasion en algerie

- fabricants d hydrosizer pour le sable de silice

- Afrique concasseur de roche cot de exploitation

- de concasseurs de roche

- broyeur des grains de sésame

- prix d une coquille de la machine de broyage

- SBM caractéristiques techniques de convoyage

- comment vérifier la force crussing de granulats de cours

- Pérou machine concasseur

- installation d unité de broyage et recyclage de la casse ceramique

- millésime meuleuse moulin solide de café en laiton rares

- laitier de haut fourneau pièces métalliques concasseur

- simons concasseur à cône

- consultant de Afrique concasseur de commission

- avantages du melangeur et du broyeur

- Quel est le technique de fonctionnement de broyeur Indonésie boulets

- poussire de broyeur prix afrique du sud

- équipement de traitement du concentrNouvelle Caldonia de cuivre de flottation

- chine concasseur en Nouvelle Caldonia Primos

- fabricants concasseur en Nouvelle Caldonia mumbai

- usine europeenne de l nrichissement du minerai de fer

- concasseur run en matang pagar

- qu"est ce que le minerai de fer

- concasseur de noix de coco utilisee dans la production de charbon casiers

- Spécifications De Concasseur

- les rapport de stage de usine Calcite ait baha

- Mines De Charbon Mp Sainik Bloc De Charbon Amelia Limité

- carrière dans les usines de ciment bosundora

- SE cru rimbolt 14mm pour broyeur