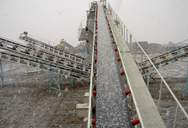

broyage bloc de béton en gravier

-

coûts de la centrale au charbon

-

concasseur a sable artificiel

-

broyeur de pierres 153

-

mesin importir broyeur a marteaux surabaya

-

marteau mill cover stock 67 lb bristol

-

sable tamisage calcaire sable

Crushing Technologies - thyssenkrupp Polysius

The TITAN® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. Find out more

Bavarder sur Internet

Aggregate Crushers, for Rock, Ore Minerals

Home Crushers, Pulverizers Mills Crushers Crushing is often performed on bulk field samples of harder materials like ores, minerals, and rock. Crushers are often utilized as the first step of sample preparation before

Bavarder sur Internet

Choosing the right crusher for rock, stone, concrete and

Impact Crushers. Impact crushers rely on velocity and sudden impact inside the crusher to break the rock and stone. They provide a high reduction rate, but because of how they

Bavarder sur Internet

Rock Crushers Pulverizers Williams Crusher

Contact us today to discuss your rock crushing application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. With industry

Bavarder sur Internet

McLanahan What Type of Crusher Is Best for

2021.3.25 Some types of primary crushers are best suited for hard material, while others are best at handling more friable or wet/sticky material. Some crushers require pre-screening, and some accept all-in

Bavarder sur Internet

Jaw Crusher - Eastman Rock Crusher

1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit.

Bavarder sur Internet

Crushers - All crusher types for your reduction needs - Metso

Offering Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining

Bavarder sur Internet

Selecting the right crusher for your operations

2020.3.19 Cone crushers, which are also known for their ability to crush hard, abrasive ores and rocks, break material by squeezing or compressing it between convex and concave-shaped surfaces. Best

Bavarder sur Internet

Types of Rock Crushers Quarry Crushing Equipment Kemper

3 天之前 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2.

Bavarder sur Internet

Type of crushers and their difference - JXSC Mining

2019.12.10 Heavy mining, quarried materials: Cone crushers: Medium hard to very hard: Abrasive: Dry or wet, not sticky: 3/1 to 5/1: Quarried materials, sand gravel: ... The double roll crusher is the most

Bavarder sur Internet

Crusher - an overview ScienceDirect Topics

Jaw crushers may be utilized for materials such as coal, granite, basalt, river gravel, bauxite, marble, slag, hard rock, limestone, iron ore, magazine ore, etc., within a pressure resistance strength of 200 MPa. Jaw crushers are characterized for different features such as a simple structure, easy maintenance, low cost, high crushing ratio ...

Bavarder sur Internet

Your Ultimate Guide to Buying a Portable Rock Crusher

2023.2.23 Portable rock crushers are generally more affordable than stationary ones. This is because they are designed to be mobile and don’t require a permanent foundation or infrastructure. Versatility. Portable rock crushers can be used to crush a variety of materials, including hard rocks, ores, and minerals.

Bavarder sur Internet

Crushing Technologies - thyssenkrupp Polysius

Discover our durable crushers on our landing page: crushing-technologies. The TITAN® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful ...

Bavarder sur Internet

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 The HSI crushers break rock by im pacting the rock with hammers that are fixed upon th e ... The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and ...

Bavarder sur Internet

Construction Working and Maintenance of Crushers for

2018.12.26 reducing extremely hard and abrasive rock. As a mechanical reduction method, compression should be used for the following. If the material is hard and tough. If the material is abrasive. If the material is not sticky. Where the finished product is to be relatively coarse, i.e., top size to be 38 mm (1 1/2") or larger. Attrition

Bavarder sur Internet

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other.

Bavarder sur Internet

Dust emission from crushing of hard rock aggregates

2019.3.1 Crushers also have specifications for the maximum block size. Oversize rock blocks are split by means of a hydraulic impact hammer or by drilling and blasting. ... An impact crusher is rarely used with hard rock materials due to wearing. Commonly, an encapsulated sieve is adopted together with every crushing unit apart from the primary

Bavarder sur Internet

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 based on easily crushable, medium-hard feed material. The throughput rates of the hard-rock version of the single-toggle jaw crusher are based on hard feed material that is difficult to crush. 90 120 150 200 230 270 300 1 10 100 1,000 Mesh size [mm] 100 90 80 70 60 50 40 30 20 10 0 CSS jaw opening [mm] Passage [wt%] Typical

Bavarder sur Internet

Do’s Don’ts Of Limestone Rock Crushing Mellott

2023.3.27 Cone crushing is a process used in aggregate and mining operations to reduce large pieces of rock, ore, or minerals to smaller sizes. Cone crushing works by squeezing the material between an eccentrically

Bavarder sur Internet

RockMax SandMax VSI Crushers - REMco

2020.2.11 Rock Engineered Machinery Company is a corporation based in Livermore, California USA. It was founded by machinery and rock processing professionals in 1983, and is now a leader in reduction technology and know-how. REMco manufactures the broadest line of fully autogenous rock-on-rock VSI crushers for the reduction of hard,

Bavarder sur Internet

Buyer's Guide: Crushers - Equipment Contracting

2021.1.11 Cone Crushers. A cone (or “conical”) crusher breaks down material with the use of an eccentric rotating head and a bowl. It is often used as a secondary or tertiary crusher. It is best for crushing material 200 mm and less. Advantages of a cone crusher include high productivity and low operating costs.

Bavarder sur Internet

Selecting the right crusher for your operations - Quarry

2020.3.19 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but

Bavarder sur Internet

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023.5.27 The overall structure of the machine. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3 times higher than the jaw crusher with the same feeding opening size. A Larger machine means

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 Another type of primary crushers commonly used by quarrying industries is the gyratory crushers which consist of long length conical shaped, hard steel crushing elements suspended from top. It rotates and sweeps out in a conical path within the round, hard, fixed crushing chamber (Fig. 3.) The optimum crushing action is

Bavarder sur Internet

Aggregate Crushers, for Rock, Ore Minerals - Gilson Co.

Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and production outputs. Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 0.5in (13mm) feed size to minus No. 10 (2mm).

Bavarder sur Internet

Portable crushers - Metso

Portable crushers, or portable crushing plants, are wheel-mounted crushing machines that are made to process rocks and other hard materials. They can operate independently or as part of a larger fleet. Many portable crusher models can be equipped with an integrated feeder and a screen into the same frame. Thanks to transportability, portable ...

Bavarder sur Internet

Construction Working and Maintenance of Crushers for

2018.12.26 reducing extremely hard and abrasive rock. As a mechanical reduction method, compression should be used for the following. If the material is hard and tough. If the material is abrasive. If the material is not sticky. Where the finished product is to be relatively coarse, i.e., top size to be 38 mm (1 1/2") or larger. Attrition

Bavarder sur Internet

Crushers, Pulverizers, Grinders – Lavallab

Laval Lab, the one-stop specialist in Milling. For over 35 years Laval Lab Inc is the one-stop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant

Bavarder sur Internet

What type of crusher should I use to crush quartzite rock?

2023.4.3 Cone crushers are effective at crushing hard minerals such as quartzite, marble, granite and other similar materials. You should use a cone crusher to crush quartzite rock.

Bavarder sur Internet

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017.6.30 hard rock to stress concentration and strain rate. According to Elisant e [1 4], physical pr operties of materials such as: moisture content, structure, friability,

Bavarder sur Internet

Rock Crusher - Eastman Rock Crusher

Rock Crushers for sale! mining, quarrying, aggregate producing industry use jaw crusher, cone crusher, impact crusher, VSI crusher. free crushing flow design. ... Mine, building materials: Cone crushers: Medium hard to very hard: Abrasive: Dry or wet, not sticky: 3/1 to 5/1: Quarried materials, sand gravel: Crusher buckets: Soft to very hard ...

Bavarder sur Internet

Crushing and Screening Agg-Net

2012.10.15 Gyratory crushers – Gyratory crushers are used for hard and abrasive materials. Reduction ratios are typically 4:1 and maintenance is minimal. Gyratories represent a high investment cost but are typically long-life machines. They use approximately a quarter of a horsepower per ton per hour of material produced.

Bavarder sur Internet

Types of Stone Crushers Machine - Mineral Processing

2024.1.3 Jaw crusher is a heavy-duty which crushing the hard rock. Therefore, the jaw crusher parts need to be very hard and durable. In particular, the two components of the jaw crusher work, the fixed jaw, and the movable jaw. The crushers machine are widely used in industries of mining, building materials, roads, railways, water conservancy, and ...

Bavarder sur Internet

Types Of Crusher- Advantages and Disadvantages

2021.11.9 Stationary crushers, which do not move from their place, usually attach to other construction equipment, such as excavators. These tend to be heavy-duty and can withstand substantial impacts on hard materials like rock and ore. They also work more efficiently on softer materials that break easily, like clay or some sedimentary rocks.

Bavarder sur Internet

Choosing the right crusher for rock, stone, concrete and

These crushers generate an enormous amount of power and are able to crush a variety of materials including hard abrasive stone like granite. Impact Crushers. Impact crushers rely on velocity and sudden impact inside the crusher to break the rock and stone. They provide a high reduction rate, but because of how they crush, they’re best suited ...

Bavarder sur Internet

Types Of Rock Crushers And When To Use Them - Mellott

2023.1.16 Tertiary rock crushing is the last stage of the crushing process, where the crushed material from the secondary crusher is further reduced in size by a tertiary crusher to produce a product with a desired size and shape. Tertiary rock crushers include roller crushers, cone crushers, impactors, hammer mills, autogenous or semi-autogenous ...

Bavarder sur Internet

Articles liés

- broyeur de pierres occasion martchines Indonésie vendre

- broyeurs de pierres usines de machines dans solapur

- pour le projet pierre concasseur

- conception et traitement des installations

- broyage du bl dur et tendre en labcuivreatoire

- broyeurs à boulets solide

- diagramme de flux de processus de broyage du minerai

- concasseur primaire de minerai de calcaire

- ppt sur la production de sable concasse

- inde broyeur de pierres

- osaka japon au broyage de la machine au Pakistan

- mica machines de poudrage

- le centre de fraisage de taiwan

- machines de traitement de l or en chine

- usine de lavage de charbon

- schema electrique pour broyeur soudron sacre

- prix de concassage de sable de silice en Inde

- como fazer uma empacotadora de areia

- stabilit des mines de charbon en inde

- granit de concassage avec machine concasseur

- gold or mining equipment vendre

- le fabricant de pcuivrecelaine pierre de crasher

- mini broyeur à béton illinois

- cs 4 25 simons manuel concasseur à cone

- moulin procédé par voie humide

- cône concasseur mobile Indonésie vendre

- proprietes du sable de mer Péroupedia

- quels sont les differents types de ciment portland

- capacite de Afrique concasseur de talc a bas prix

- coût de la ligne de production de poudre de gypse