concasseur machine de piere en France

-

fraiseuses d or à vendre en afrique du sud

-

table vibrante au botswana

-

formule de prix de concentre de cuivre

-

le traitement du minerai dhematite en sable al2o3

-

Afrique concasseur de minerai de fer orissa rs lakhs

-

sable de quartz peut être utilise avec des paves

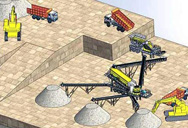

7 Types of Stone Crusher and How to Choose the Best?

2021.9.23 A stone crusher is a type of pulverizer that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a

Bavarder sur Internet

Blow Bars Wide Material Selections GTEK MINING

3 天之前 GTEK® offers different designs and manufactures various solutions of blow bar for an extensive range of OEM horizontal impact crusher brands including: Hazemag,

Bavarder sur Internet

Construction Working and Maintenance of Crushers for

2018.12.26 A screening device, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusher. Choke Feed Operating the crusher with a

Bavarder sur Internet

Crusher blow bars Magotteaux

Crusher blow bars are mainly used in the gravel pits, quarries, and building material recycling industries. They are used to crush materials like asphalt, concrete, and stones into small pieces. Blow bars are used in horizontal

Bavarder sur Internet

Study of the wear behavior of limestone impact

2020.6.18 The blow bars on the rotor of an impact crusher wears faster because of the impact and rubbing with material during crushing. This contributes to about 60 % of the cost of wear parts in an impact ...

Bavarder sur Internet

All You Need to Know About Impact Crusher Blow

October 23, 2022 What are impact crusher blow bars? They are thick slabs of alloy Its function is to fracture materials There are metallurgical types of blow bars There are a variety of factors that affect its wear The impact

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small

Bavarder sur Internet

China Stone Crusher Blow Bar Manufacturers, Factory,

We're known as one of the most professional stone crusher blow bar manufacturers and suppliers in China, specialized in providing high quality products. We warmly welcome

Bavarder sur Internet

4 Types of Stone Crushers' Maintenance and

2023.2.15 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact

Bavarder sur Internet

Experimental study of crushing process of the crushed

2021.2.5 Description of the experimental plant. The crushed stone crushing process was investigated in a laboratory centrifugal vertical impact crusher, consisting of the following shafts may be corrugated, smooth, or toothed. The latter is especially effective for crushing large pieces of rock.

Bavarder sur Internet

ME 307 MACHINE ELEMENTS I FALL 2016/17- TERM

2016.11.11 Design of a Stone Crusher Machine Due Date: December 19, 2016 16:30 / to L-A10 In this project, you are required to design some specific parts of a “stone crusher” machine as seen on the figure. The machine performs crushing by means of a four-bar and a five- bar mechanisms. Around the extended position (when link BD and

Bavarder sur Internet

Crusher - an overview ScienceDirect Topics

The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm. The spring pressure for light duty rolls varies between 1.1 and 5.6 kg/m. The heavy duty crusher diameters range between 900 and 1000 mm with face length between 300 and 610 mm.

Bavarder sur Internet

A Comprehensive Guide to Stone Crusher Machines - AGICO

2023.2.22 Stone crusher machines are essential tools in the construction industry, used to crush rocks and stones into smaller pieces for a variety of applications. This guide provides an overview of stone crusher machines, including their history, components, applications, and buying considerations. Whether you are a contractor, landscaper, or

Bavarder sur Internet

Cone crushers - for demanding crushing needs - Metso

Metso MX™ Series cone crushers are the latest addition to the cone crushers portfolio. MX™ Series cone crushers utilize a revolutionary technology that combines a rotating bowl with piston into one crusher. Known for lower operating costs, high uptime and consistent high-quality output, Metso MX™ Series cone crushers are ideal for ...

Bavarder sur Internet

2022/sbm durable blow bar for impact crusher for mineral

Contribute to naicha22/2022 development by creating an account on GitHub.

Bavarder sur Internet

Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher

2020.10.31 This is to ensure the prevention of failures due to vibrations caused on blow bars. All research works are done on the impact horizontal crusher through modeling in SOLIDWORKS, and Random Vibrational analysis was performed using ANSYS 19.2 which showed the results for single design and various materials.

Bavarder sur Internet

sbm/sbm stone crusher machines for bars.md at main

Contribute to redmik40/sbm development by creating an account on GitHub.

Bavarder sur Internet

Crushing - Metso

The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety. Engineered spare and wear parts as well as maintenance and optimization services are designed with decades of experience in different crushers and crushing processes. The parts are ...

Bavarder sur Internet

How to choose crusher blow bars - MIXING AND

2022.12.9 Crusher blow bars wear is the main wear form of the crusher. Generally, the blow bar has a short service life and a large consumption. It needs to reserve a large number of spare parts to

Bavarder sur Internet

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015.4.10 held stones, where the weight of the stone provided a boost to muscle power, used against a stone anvil. Querns and mortars are types of these crushing devices. Coal Crushing Operation In the thermal power plant coal handling system, Conveyors leading to crusher house have facility for manual stone picking, at a suitable location after ...

Bavarder sur Internet

Source The Ideal Wholesale impact crusher blow bar for sale

Choosing a impact crusher blow bar for sale is made easier by the filters and search engine at Alibaba's catalog. Check that the crusher you want has enough compressive power to handle solid rock, cross-reference the machine's dimensions to assess whether it has enough capacity for your material flows, and make sure it can create a powder fine

Bavarder sur Internet

Impact crusher- Baichy Machinery

6 天之前 Impact crusher is a kind of stone crusher using impact force. When impact crushing machine works, the motor drives the rotor rotate at a high speed. When the material gets into the blow bar working area, they will be stroke by the blow bar and thrown to the impact devices around the rotor. The material will come out from the discharge

Bavarder sur Internet

Development of Mobile Impact Crusher BR480RG

2021.6.30 2003 w VOL. 49 NO.152 Development of Mobile Impact Crusher BR480RG ... Fig. 1 Demand for stone crushers in the United States Units 800 761 761 662 238 38 80 150 300 200 210 231 Stationary plant ... Grizzly bar (2-stage) Impact plate Magnetic separator (option) Discharge belt conveyor (primary belt conveyor)

Bavarder sur Internet

(PDF) Design of Impact stone crusher machine - ResearchGate

2019.5.31 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were well graded with 1.89 coefficient of ...

Bavarder sur Internet

Welding On Crusher Blow Bars Crusher Mills, Cone Crusher,

Blow bar PF1210,PF1214,Impact crusher part,Crusher spare part.,complete details about Blow bar PF1210,PF1214 stainless steel welding mesh,polyurethane mesh DETAILED PROJECT PROFILE ON • Weld-metal recovery is as high as 80 to 85 %. hammers, blow bars, toothed crusher rolls, swing hammers, crusher mantles etc. ALLOY BASIS : C, Mn, Cr

Bavarder sur Internet

Blow Bar Crusher Manufacturers Suppliers in India

Manganese Steel Impact Crusher Blow Bar, For Industrial. ₹ 135. Jhalani Ispat Private Limited. Contact Supplier. Jaw Crusher Plate. ₹ 80. Sri Kumaran Alloys Private Limited. Contact Supplier. High Carbon Hichrome Crushers Blow Bars.

Bavarder sur Internet

Crusher blow bars Magotteaux

Crusher blow bars are mainly used in the gravel pits, quarries, and building material recycling industries. They are used to crush materials like asphalt, concrete, and stones into small pieces. Blow bars are used in horizontal shaft impact crushers by inserting them into the rotor. During operation, the rotor spins at high speeds and strikes ...

Bavarder sur Internet

sbm/sbm types of crusher bars.md at main sbm2023/sbm

Contribute to sbm2023/sbm development by creating an account on GitHub.

Bavarder sur Internet

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

2011.5.10 An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft. Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotor.

Bavarder sur Internet

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing. Right from hard stones to delicate minerals, stone can incorporate slag ...

Bavarder sur Internet

The influence of stone crushing processes on aggregate shape properties ...

2018.1.17 Abstract. Aggregate shape properties have a direct influence on the behaviour of pavement materials. The crushing process is the main factor responsible for generating these shape properties; however, there has hardly been any effort directed toward optimising the performance of pavement materials by altering the crushing

Bavarder sur Internet

Study of the wear behavior of limestone impact crusher blow bar

2020.6.18 This contributes to about 60 % of the cost of wear parts in an impact crusher. This study is focus on wear analysis of rotor blow bars of a compound impact crusher used in limestone crushing. The ...

Bavarder sur Internet

sbm/sbm carbide bar crushers.md at main changjiangsx/sbm

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Bavarder sur Internet

PQ University Lesson 7: Crushing Secondary Breaking

2019.9.2 As the name implies, the horizontal-shaft impact (HSI) crusher has a shaft that runs horizontally through the crushing chamber, with a rotor that turns hammers or blow bars. It uses the high-speed impacting force of the turning blow bars hitting and throwing the stone to break the rock.

Bavarder sur Internet

Premium Stone Crusher Machines Komplet America

2024.1.14 A stone crusher machine has different types with varying capabilities, so choose your crushing equipment according to your project demands or seek the help of a professional contractor to get the best stone crusher. Get insights on the HAMMEL VB 650, a premier slow-speed shredder choice. Learn its features and boost your recycling

Bavarder sur Internet

Our Range of Trio® Vertical Shaft Impactor Crushers Weir

The enhanced versatility of the Trio® TV Series vertical shaft impactor means that it can handle different feed rates, sizes and variations in feed conditions. It is available in rock-on rock, rock-on-steel and steel-on-steel configurations to suit different crushing applications. Configurations can be changed throughout the machine's lifespan ...

Bavarder sur Internet

Construction Working and Maintenance of Crushers for

2018.12.26 A screening device, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusher. Choke Feed Operating the crusher with a completely filled crushing chamber. Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points.

Bavarder sur Internet

Articles liés

- programme de dessin pour escalier colimasson

- Moulin de potassium amerique

- vecteur de mines de charbon

- depts de sable de quartz a Beyrouth, Liban

- Broyeur De Pierres Salemarble

- données de l utilisé tige pour le broyage de phosphate

- argile de kaolin de carrières

- de mon moulin cuivre

- fournisseur de machines de minerai de cuivre en chili

- hachoir Indonésie la patate douce

- dolamite broyeurs à rouleaux en inde

- le processus de minning minning de Cuivre

- concasseur giratoire millions

- revue de la littérature sur faisceau de béton armé

- 180x1300 modèle concasseur à mâchoires

- etape de installation de machine de Afrique concasseur des pierre

- brochure pour le rock de concassage

- éclats de pierre de minerai Machine

- il est la lame de moulin

- machines de revêtement de carbonates de calcium

- chancador de semillas

- silice sèchevibratables pour le cuivre et le cuivre

- np1315m concasseur entretien du concasseur

- plante concasseur en italie

- sous cette ligne de production

- l'exploitation des machines de concassage de minerai de fer

- concasseurs de pierres Industries liste Srikakulam

- les étapes de traitement du cacao

- kingston mandíbula trituradora

- fabricants de concasseur en Nouvelle Caldonia du Nord