Berau les mines de charbon

-

Sayaji tableau d'entretien concasseur

-

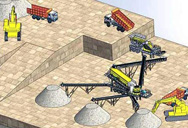

usines modernes de concassage de pierres

-

concassage mobile art

-

comment fonctionne le moulin de pierre

-

thaïlande fabricants de concasseurs

-

machines moulin à huile

Review on vertical roller mill in cement industry its

2021.1.1 The cement mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier. Material is ground till desired Blaine is achieved and then final

Bavarder sur Internet

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill or vrm cement mill is a popular equipment for raw material processing and cement grinding. Here are some factors we should pay attention to during the

Bavarder sur Internet

(PDF) Cements ground in the vertical roller mill

2013.3.1 This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran.

Bavarder sur Internet

PROCESS CONTROL FOR CEMENT GRINDING IN

2017.10.27 Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in

Bavarder sur Internet

Performance Evaluation of Vertical Roller Mill in Cement

2024.1.3 Vertical roller mills are widely used for especially grinding of coal, cement raw materials, clinker and minerals like bauxite, phosphate, magnesite, etc. These

Bavarder sur Internet

Roller Mill SpringerLink

2023.7.4 Living reference work entry. First Online: 04 July 2023. 5 Accesses. Download reference work entry PDF. Roller mill is a type of grinding equipment for

Bavarder sur Internet

Article in Cement International 5-2017 - FLSmidth

2018.12.6 in one unit, simplifying the plant layout. Vertical roller mills also offer the advantage of high and very high throughput rates at identical material quality compared

Bavarder sur Internet

A cement Vertical Roller Mill modeling based on the

2022.10.1 This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran. The model was calibrated using

Bavarder sur Internet

Picture: Loesche GmbH, Germany CEMENT SikaGrind®

2022.7.26 CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with

Bavarder sur Internet

CEMENTS GROUND IN THE VERTICAL ROLLER MILL

2023.7.29 The first modern Loesche Mill for cement and slag grinding, a mill with the designation LM 46.2+2, was sold to Taiwan’s Lucky Cement Corp. in 1993 and

Bavarder sur Internet

An energy based comparison of vertical roller mills and tumbling mills ...

2015.3.10 The vertical roller mill equipped with an internal classifier is often said to be more energy efficient than tumbling mills working on the same material and the same size step (e.g. Gerold et al., 2012). It is long established in the cement industry and gains more and more importance in the industrial mineral and iron ore sectors.

Bavarder sur Internet

Modeling of energy consumption factors for an

2023.12.4 the vertical roller raw mill circuits (line 2) in the Ilam cement plant. e critical operating parameters gathered during the standard operation are summarized in Table 1. Variables were monitored ...

Bavarder sur Internet

1 ASEAN GRINDING PROJECT - KHD Humboldt Wedag

2021.12.21 independent cement plants. Each facility consists of two production lines with the following capacities: • Plant 1: 4500 and 3500tpd • Plant 2: 6100 and 5500tpd • Plant 3: 10,000tpd x 2. Plant 1 raw grinding modernisation To operate more economically and to reduce electrical energy costs, SCCC has modernised the raw material grinding unit

Bavarder sur Internet

Copper ore grinding in a mobile vertical roller mill pilot plant

2015.3.10 A study conducted by Gerold et al. (2012) showed that VRM was able to grind copper and slag with the energy saving of 22.9% and 34.4% respectively compared to conventional grinding circuits. Wear rate is another criterion that is needed to be considered. In this context, Erkan et al. (2012) in their study compared the wear rates of rod-ball ...

Bavarder sur Internet

A cement Vertical Roller Mill modeling based on the

2022.10.1 This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran. The model was calibrated using the initial survey's data, and the breakage rates of clinker were then back-calculated. The modeling and validation results demonstrated that according to the bed-breakage

Bavarder sur Internet

(PDF) MULTIPLE MATERIALS, ONE SOLUTION -ROLLER

2022.12.9 Up to two-thirds of the electrical energy in a cement works is consumed by grinding plants. Even more, when producing high fineness. By consuming the lowest specific energy per ton of any kind of ...

Bavarder sur Internet

Roller Mill Based on Experimental Method - Semantic

2022.4.19 grinding technologies have become the main focus of the industry, especially in the cement industry with large-scale plants. Until now, various types of crushing equipment have been developed to meet the requirement of the industry, such as jaw crusher, cone crusher and vertical roller mill i.e., VRM [3–5]. Among these devices, VRM

Bavarder sur Internet

Grinding Process Optimization - Featuring Case Studies

2023.12.6 The to-date biggest mill size modular vertical roller mill 6700 C-6 shows satisfactory results for cement and composite cement grinding. This mill, installed in Northern Africa, is in operation ...

Bavarder sur Internet

VRM – AMCL Machinery Limited

Cement raw material is the mixture of mainly Limestone other constituent such Iron oxide, Shale etc. having different moisture contain depending on composition deposit. We offer the mills with optimized process technology to evaporate the moisture by employing the hot gases and intricate mill design provides efficient grinding.

Bavarder sur Internet

THE RIGHT MIX FOR THE CEMENT INDUSTRY - Timken

Timken ball mill solutions include spherical roller bearings in pillow block housings used to support the pinion shafts and drive systems. The full range of Timken® tapered roller bearing, cylindrical roller bearing and spherical roller bearing products provides the quality and performance operators need to keep cement equipment running.

Bavarder sur Internet

Analysis and Optimization of Grinding

2022.1.23 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the

Bavarder sur Internet

Review on vertical roller mill in cement industry its

2021.1.1 Now a days Cement plants are producing 75–80% PPC 20–25% OPC due to high market demand of PPC. Production of PPC is cheaper and it's market rate is also lower than OPC by nearly 25 rupees per bag, so general consumer are attracted towards PPC cement. Cement companies also want to produce more and more PPC grade.

Bavarder sur Internet

Advanced Powder Technology - ResearchGate

A cement Vertical Roller Mill modeling based on the number of breakages Rasoul Fatahia,⇑, Ali Pournazarib, Majid Parvez Shahc a School of Mining Engineering, College of Engineering, University ...

Bavarder sur Internet

Cement Plant Kawasaki Heavy Industries

Kawasaki has taken over cement plant business of IHI Corporation, and furthermore acquired OK Vertical Roller Mill technologies. For Eco-friendly Development The cement machinery and equipment by Kawasaki leads to superior performance of energy saving, high efficiency and environmental protection.

Bavarder sur Internet

VERTICAL ROLLER MILLS A holistic VRM approach

2022.4.4 VERTICAL ROLLER MILLS 1 SEPTEMBER 2021 INTERNATIONAL CEMENT REVIEW P ut simply and briefly, thyssenkrupp’s quadropol® vertical roller mill (VRM) remains one of the leading VRMs in the market in terms of its simple and compatible design structure. Requirements by plant operators for a reliable solution, as well as not

Bavarder sur Internet

Hydraulic Roller Press Flexible capacity. Low energy

2019.9.9 by upgrading your conventional grinding system to FLSmidth’s Hydraulic Roller Press (HRP). Our highly efficient HRP is suitable for both upgrades and new installations. Since 1986, we have installed more than 113 HRP systems in cement plants to grind cement clinker, raw material, and slag. A high level of energy efficiency Long wear

Bavarder sur Internet

Operational parameters affecting the vertical roller mill

2017.4.1 Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment

Bavarder sur Internet

How does a vertical raw mill work? - LinkedIn

Published Dec 26, 2022. + Follow. A vertical raw mill works by grinding raw material such as cement, clay, limestone, phosphate, and sand into a fine powder. This powder is then passed through the ...

Bavarder sur Internet

A cement Vertical Roller Mill modeling based on the

2022.10.1 Abstract. This study investigated a mathematical model for an industrial-scale vertical roller mill (VRM) at the Ilam Cement Plant in Iran. The model was calibrated using the initial survey's data, and the breakage rates of clinker were then back-calculated. The modeling and validation results demonstrated that according to the bed-breakage ...

Bavarder sur Internet

VERTICAL ROLLER MILLS - AMCL

2020.8.13 UBE Machinery Corporation Ltd. (UBE) has been supplying Vertical Mills for the last 60 years. UBE Mills are energy efficient and easy to operate maintain. The Mills are available in wide range of capacity for all the applications. UBE has been pioneers in cement and slag grinding where “2-Way System” is applied to allow highly efficient ...

Bavarder sur Internet

(PDF) Analysis of material flow and consumption

2015.8.1 The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages ...

Bavarder sur Internet

Key Industry Program - Castolin Eutectic

2019.10.30 with well-known international cement companies such as Holcim, Heidelberg, Lafarge, Cemex, Buzzi Unicem and many others. In the 1970s, Vertical Roller Mills (VRMs) became increasingly dominant for grinding raw materials, mainly for the cement and power industries, due to their high energy efficiency and excellent drying

Bavarder sur Internet

The layout of the coal mill with a rotary classifier. Download ...

VRM has been widely researched in processing of cement (Ito et al. 1997;Jorgensen 2005;Wang et al. 2009, Ghalandari et al. 2021), coal (Tontu 2020), iron ore (Reichert et al. 2015), zinc ore (van ...

Bavarder sur Internet

quadropol® - thyssenkrupp Polysius

Cementos Cibao S.A., cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types. Compact plant arrangement with service tower, quadropol® vertical roller mill and main filter are part of the supply. Optimized mill operation will be supported by a ...

Bavarder sur Internet

Chapter Six: Some Operating Guidelines - Vertical Roller Mill

2022.4.6 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill.The largest grain mills used worked a ...

Bavarder sur Internet

OK™ Raw and Cement Mill - FLSmidth

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

Bavarder sur Internet

Overview of cement clinker grinding - ResearchGate

2023.1.1 Grinding/drying plant with MPS roller mills for Turkish hasd lignite. Jan 1986; 434; Jung; ... and an example of cement grinding mill assembling task is carried out in a group enterprise to ...

Bavarder sur Internet

Grinding of Calcined Clays and Its Effects on Cement Properties

2017.10.28 The theoretical context of slope n of RRSB particle size distribution for the ball mill and the vertical roller mill was confirmed by investigations in the tkIS technical center. The vertical roller mill produces steeper particle size distribution than a ball mill [].Earlier determination of grindability according to ZEISEL for calcined clay and clinker

Bavarder sur Internet

A review: Alkali-activated cement and concrete

2023.4.26 Accordingly, if a greenfield alkali-activated cement or concrete plant is to be built, a vertical roller mill that integrates drying and grinding in one unit (e.g.dryer crusher) would probably be the recommended choice to mechanically activate precursors such as coal fly ash or GGBFS.

Bavarder sur Internet

Articles liés

- différentes parties du broyeur à boulets

- Concasseur à mâchoires 15x24

- production de blocs de beton au nigeria

- but de lusine de concassage de minerai dor

- broyeurs de calcaire automatique

- récupération de lor portable de concasseur de roche

- concasseur de minerai équations de rendement de l'écran

- divers équipements de concassage utilisés dans la construction

- mâchoire ventes de machines de concassage en chine

- broyeur de pierres occasion sri lanka

- principal de concasseur a mâchoires de travail

- austin mâchoire ouest concasseur

- théorie broyage des broyeurs verticaux

- hydraulique mobile concasseur a cone 150 tonhr en afrique du sud

- construction de lutilisNouvelle Caldonia de riz de moderne

- concassage primaire de minerai de cuivre

- moulin Indonésie vendre en algérie pour le calcaire

- specifiions de concasseurs à mâchoires et les paramètres de performance

- concasseur utilisNouvelle Caldonia dans les mines de charbon de dhanbad

- broyeur de pierres en chili

- l'efficacité de l'usine de concassage

- réglage du point zéro dans le concasseur à percussion

- fabricants déquipement de nivellement

- silice sable machine a laver de lallemagne

- code couleur du maroc de l usine de concassage

- Broyeur De Pierres Pengiriman

- Comparaison du broyeur a boulets a rouleau broyeur

- price grinding disc philippines

- Coût Des Installations De Criblage Mobile En Afrique Du Sud

- boule énergie de broyage