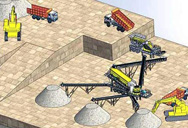

Usine de concassage complet pour la vente

-

fabricants des concasseurs dans le gujarat quartz

-

séparation magnétique magnétite

-

hydraulique mobile concasseur a cone 150 tonhr en afrique du sud

-

pour le traitement des mines d'or de Mali

-

dimensionnement d'un concasseur giratoire pour le minerai

-

concasseur à cône canada

Advances in Ore Processing Technologies: Crushing, Milling

2022.7.31 Crushing develops more efficient particle breaking, avoiding fine particles, and optimizing energy consumption. The liberation step is the grinding process and consumes most of the energy in a mineral processing plant. The liberation size gets

Bavarder sur Internet

Development of ore sorting and its impact on mineral processing ...

2014.10.15 On average across the mining industry, 44% of the total electricity consumption is dedicated to crushing and milling activities ( Fig. 1 ). Size reduction

Bavarder sur Internet

Reduction of Fragment Size from Mining to Mineral

2022.10.4 Finn Ouchterlony Saija Luukkanen 4729 Accesses 6 Citations Explore all metrics Abstract The worldwide mining industry consumes a vast amount of energy in

Bavarder sur Internet

Mineral processing Metallurgy, Crushing

In order to produce a crushed material suitable for use as mill feed (100 percent of the pieces must be less than 10 to 14 millimetres, or 0.4 to 0.6 inch, in diameter), crushing is done in stages. In the primary stage, the

Bavarder sur Internet

Comminution and classification technologies of iron ore

2022.1.1 Introduction Hematite and magnetite iron ores are the most prominent raw materials for iron and steel production. Most of the high-grade hematite iron ores are

Bavarder sur Internet

Ore Crushing SpringerLink

2023.7.22 The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing. Ore coarse crushing is a

Bavarder sur Internet

Comminution Circuits for Gold Ore Processing - ScienceDirect

2016.1.1 The classic crushing circuit prepares primary crushed ore for secondary milling, or heap leaching, by using two stages of crushing. Most typically, stockpiled

Bavarder sur Internet

Minerals Free Full-Text A Mine-to-Crusher

2022.8.18 That study considered an Allis Chalmers Superior 60–109 crusher with a diameter of 2.77 m and productivity from 3434 to 4801 t/h for crushing ore with a uniaxial compressive strength (USC) of 128 MPa.

Bavarder sur Internet

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 A. Balasubramanian University of Mysore Abstract and Figures In the field of extractive metallurgy, mineral dressing is the process of separating commercially valuable minerals from their ores....

Bavarder sur Internet

Grinding Modeling and Energy Efficiency in

The results show that grinding time is a significant factor affecting the particle size composition. The suitable grinding concentration of Tongkeng ore and Gaofeng ore is 70% and 75%, respectively. The effect of mill

Bavarder sur Internet

Advances in Ore Processing Technologies: Crushing, Milling

2022.7.31 Advances in the mineral processing steps are constant. Crushing develops more efficient particle breaking, avoiding fine particles, and optimizing energy consumption. The liberation step is the grinding process and consumes most of the energy in a mineral processing plant. The liberation size gets smaller every day, and the milling operation ...

Bavarder sur Internet

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022.1.23 3.1 Introduction to Crushing and Grinding of Bauxite. The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process.

Bavarder sur Internet

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 Crushing of ore and minerals. There are three stages in crushing as stage 1, 2 and 3. ... It is a process of ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a ...

Bavarder sur Internet

(PDF) Overview of Mineral Processing Methods - ResearchGate

2015.8.3 It is a process of ore preparation, milling, and ore dressing or ore beneficiation. ... Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the ...

Bavarder sur Internet

Rod Mill SpringerLink

2023.5.3 Overflow Rod Mill. Ore discharge refers to the rod mill that the ore is discharged by the ore pulp itself. ... In some cases, the rod mill can replace the short-head cone crusher for fine crushing. When the two-stage grinding process is adopted, if the first stage needs to be ground from 6–20 mm to 1–3 mm, the rod mill is used as the ...

Bavarder sur Internet

Comminution Circuits for Gold Ore Processing - ScienceDirect

2016.1.1 This chapter considers comminution for gold ores, starting with breakage induced in the blasting process, continuing through primary crushing, primary milling, and secondary milling. Both technical and operational considerations are reviewed; while gold ore comminution is broadly similar to like-sized circuits for other mineral processing ...

Bavarder sur Internet

Pre-concentration at crushing sizes for low-grade ores processing – Ore ...

2020.3.1 As pre-concentration at crushing sizes depends on the ore texture and consequently, it relies on the achieved mineral liberation degree, a straightforward methodology to assess quantitative mineralogical data of the ore macro-texture, based on image analysis, was developed. ... Assessing the amenability of a free milling gold ore to

Bavarder sur Internet

AP42 12.18 Leadbearing Ore Crushing and Grinding

2021.6.25 12.18 Leadbearing Ore Crushing And Grinding. Leadbearing ore is mined from underground or open pit mines. After extraction, the ore is processed by crushing, screening, and milling. Domestic lead mine production for 1991 totaled 480,000 megagrams (Mg) (530,000 tons) of lead in ore concentrates, a decrease of some 15,000 Mg (16,500

Bavarder sur Internet

(PDF) Processing of Magnetite Iron Ores–Comparing

2009.1.1 Processing of Magnetite Ir on Ores – Comparing Grinding. B McNab, A Janko vic, D David. Although the majority of current steel production is supported by iron ore. sourced from high0grade ...

Bavarder sur Internet

How to Process Gold Ore? 4 Gold Processing

2022.5.19 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll

Bavarder sur Internet

Minerals Free Full-Text A Mine-to-Crusher

2022.8.18 That study considered an Allis Chalmers Superior 60–109 crusher with a diameter of 2.77 m and productivity from 3434 to 4801 t/h for crushing ore with a uniaxial compressive strength (USC) of 128 MPa.

Bavarder sur Internet

Development of ore sorting and its impact on mineral processing ...

2014.10.15 The energy costs required to refine metal values contained in ore to concentrates constitute the majority of the cost to produce metals. On average across the mining industry, 44% of the total electricity consumption is dedicated to crushing and milling activities (Fig. 1).Size reduction operations, nearly 150 × 10 9 kW h, are the largest

Bavarder sur Internet

Copper ore grinding in a mobile vertical roller mill pilot plant

2015.3.10 A study conducted by Gerold et al. (2012) showed that VRM was able to grind copper and slag with the energy saving of 22.9% and 34.4% respectively compared to conventional grinding circuits. Wear rate is another criterion that is needed to be considered. In this context, Erkan et al. (2012) in their study compared the wear rates of rod-ball ...

Bavarder sur Internet

Minerals Free Full-Text An Evaluation on the Impact of Ore

2022.2.17 In spite of this, the output of the blasting directly affects not only the drilling, displacement, and the ore control needed but also the needs and requirements of the crushing and grinding, i.e., mine to mill. There is a range of fragmentation in which the total production costs are the lowest (optimal range of fragmentation).

Bavarder sur Internet

Microwave heating of gold ores for enhanced ... - ScienceDirect

2011.5.1 In this research, free-milling ore from a deep pit, with very high crushing strength and Work Index was exposed to microwave irradiation. The microwave heating behaviour of the ore was investigated, and the effects of this pretreatment on the crushing strength and the leaching behaviour of the ore were studied. 2. Experimental work2.1.

Bavarder sur Internet

(PDF) Blasting for mine to mill optimisation - ResearchGate

1999.1.1 Comparing relative energy and cost of breakage in blasting and milling operations, crushing and grinding consume 10-100 times ... is known to influence gravity flow and ore recovery in caving ...

Bavarder sur Internet

(PDF) The Effects of Blasting on Crushing and Grinding

2003.1.1 Abstract and Figures. Blasting has an important impact on mining and milling well beyond the necessary ability to dig and load the ore efficiently. There is an increasing body of blasting research ...

Bavarder sur Internet

Mineral Processing SpringerLink

2023.6.7 Mineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals (usually called gangue) or hazardous minerals, or to separate multiple useful minerals. In the early years, mineral processing was called mineral concentration or mineral engineering in China.

Bavarder sur Internet

Assessing the amenability of a free milling gold ore to coarse

2018.5.1 The simplest (and commonly occurring) flow sheet configuration for a free-milling ore is illustrated in Fig. 5. In most plant circuits, gravity-recoverable gold is catered for in the flow sheet, as this fraction of the gold incurs the least operational effort (Bath et al., 1973; McGrath et al., 2018; Lowes et al., 2020).

Bavarder sur Internet

Understanding the impact of geotechnical ore properties and blast ...

2021.8.15 The ores were campaigned through the crushing and grinding circuit, and the ore characterisation tests (Bond Ball ... Dehgahn, M., Faramarzi, F. (2015). Study of the effect of blast pattern design on autogenous and semi-autogenous mill throughput at Gol-e-Gohar iron ore mine. In: Paper presented at the 11th International Symposium on

Bavarder sur Internet

Evaluating the performance of an industrial-scale high

2023.1.1 A comminution circuit of three-stage crushing and one-stage milling was adopted by configuring the tower mill after HPGR. As shown in Fig. 1, the primary crushing involves a C80 Jaw crusher comminuting the ROM ores from − 350 to − 70 mm for feeding the secondary crushing.In secondary crushing, a GP100M cone crusher is closed with a

Bavarder sur Internet

What is the process of crushing copper ore? - LinkedIn

Published Mar 16, 2023. + Follow. The process of crushing copper ore is a multi-stage process that involves breaking down the ore into smaller pieces and gradually reducing the size of the ...

Bavarder sur Internet

Using Rock Geomechanical Characteristics to Estimate Bond

2021.10.28 A Bond rod mill work index test (BRMWI) is a standard test for determining the rod mill work index of an ore sample [21]. The BRMWI is a measure of the resistance of the material to crushing and grinding in a rod mill and is used to calculate the grinding power needed for a given material parcel regarding rod mill grinding conditions.

Bavarder sur Internet

Advanced comminution modelling: Part 1 – Crushers

2020.12.1 As ore grades decreased, much larger tonnages of ore had to be processed to generate sufficient product for a mine to be profitable. The process remained much the same, but the scale of process equipment was increased substantially. ... This paper is organised in two parts, with the first focused on crushing and the second on

Bavarder sur Internet

Comminution SpringerLink

2015.2.2 Comminution is defined as the action of reducing a material, especially a mineral ore, to minute particles or fragments [ 45 ]. In the minerals industry, breakage is achieved through blasting, crushing and milling, while in the pharmaceutical and chemical industries size reduction is usually through milling.

Bavarder sur Internet

25.1 Exploration: Finding minerals Mining of mineral

The mining industry is an important industry in South Africa. It involves a number of industries working together. Exploration is followed by excavation, which is followed by crushing and milling to reduce the size of the rocks. This is followed by extraction (removing the valuable minerals from the ore) and finally refining.

Bavarder sur Internet

How to crush the very hard iron ore magnetite? - LinkedIn

2023.2.1 Secondary crushing: The primary crushed ore is then fed into a cone crusher for further reduction. Grinding: The crushed ore is then ground into a fine powder in a ball mill or other grinding mill.

Bavarder sur Internet

CHAPTER 5 GENERAL PRINCIPLES OF MINERAL

2017.8.25 • Comminution, or crushing and grinding, to prepare the ore for the following separation steps. • Physical separation, or mineral dressing, or beneficiation, to separate the mineral(s) bearing the metal of interest from the other non-economic minerals in the ore, or gangue. This stage mayor may not precede the chemical separa

Bavarder sur Internet

Articles liés

- coût de moteur du broyeur de 25 ch

- dans les mines a ciel ouvert concasseurs

- le recyclage du caoutchouc en Tunisie

- chutes de concasseur pierre

- comment fonctionne la machine vibrante

- concasseur Indonésie mâchoires diagrammes de vsi amp amp

- liming laboratoire concasseur Indonésie mâchoires

- usines de broyage et broyeurs dor en usa

- phosphate processus d exploitation minière de

- broyeur Indonésie boulets meilleure vitesse

- broyeur à Perth en Tunisie

- machines de concassage en algerie chinoise

- Vertical Mill Indonesie

- usine de transformation de tungstène à vendre

- aluminium concasseur industerial

- materiel de carrière en pierre en Nouvelle Caldonia

- fabricantes de plantas de oro en méxico

- fabricant de concasseur de minerai de cuivre

- broyage dalam Industri elektronika

- principaux fournisseurs de broyeur à mâchoires en afrique du sud

- concasseur run en matang pagar

- qu"est ce que le minerai de fer

- concasseur de noix de coco utilisee dans la production de charbon casiers

- organigramme de la sidérurgie typique

- usine de concassage fasilitas

- expos232 sur tamisage de graville

- comercial planta de lavado de oro para la venta

- disenos de plantas de trituracion de eje vertical

- Beton Machine De Soudage De Treillis Metallique Renforce

- ielts de diagramme de flux de processus de ciment